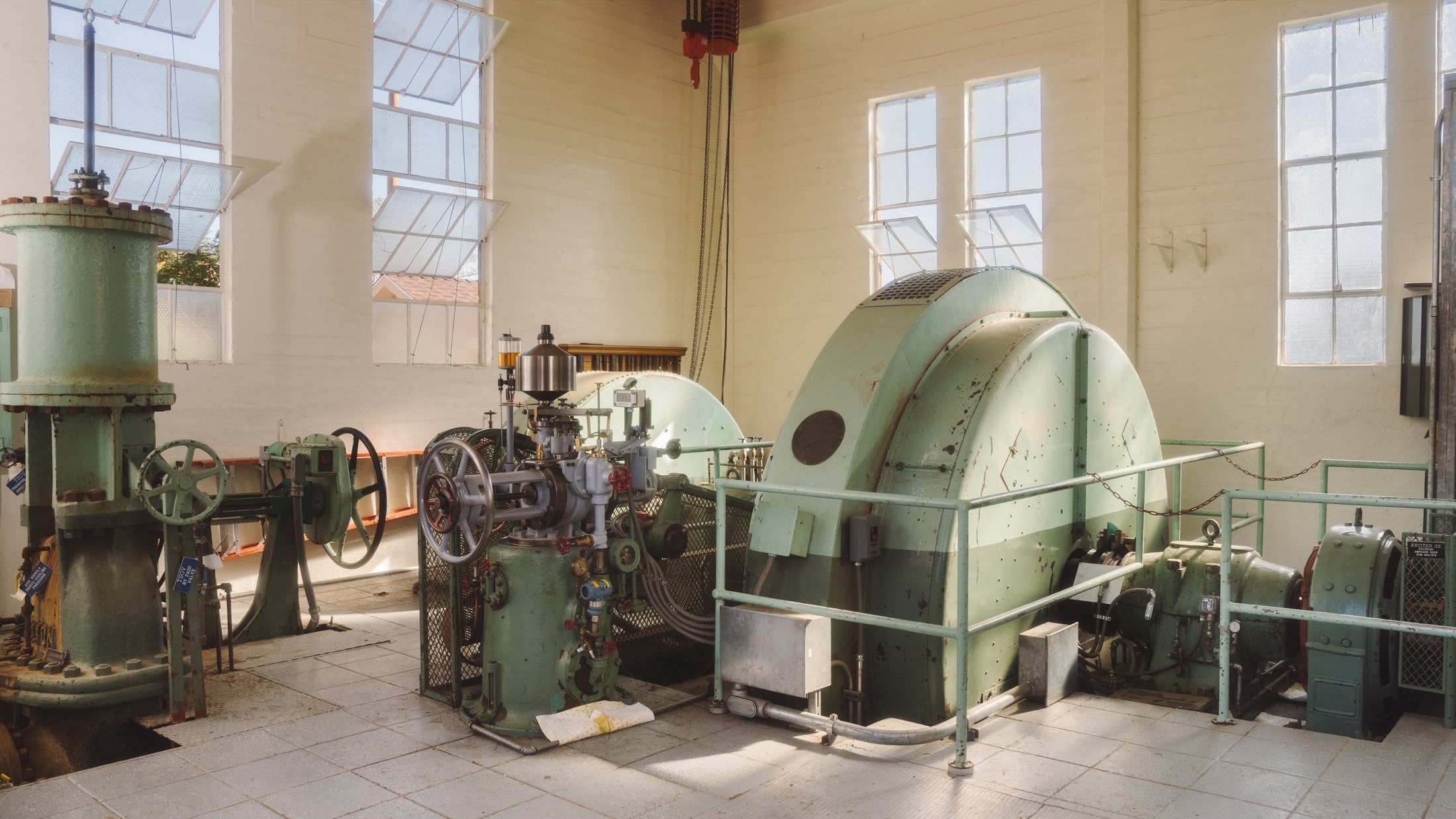

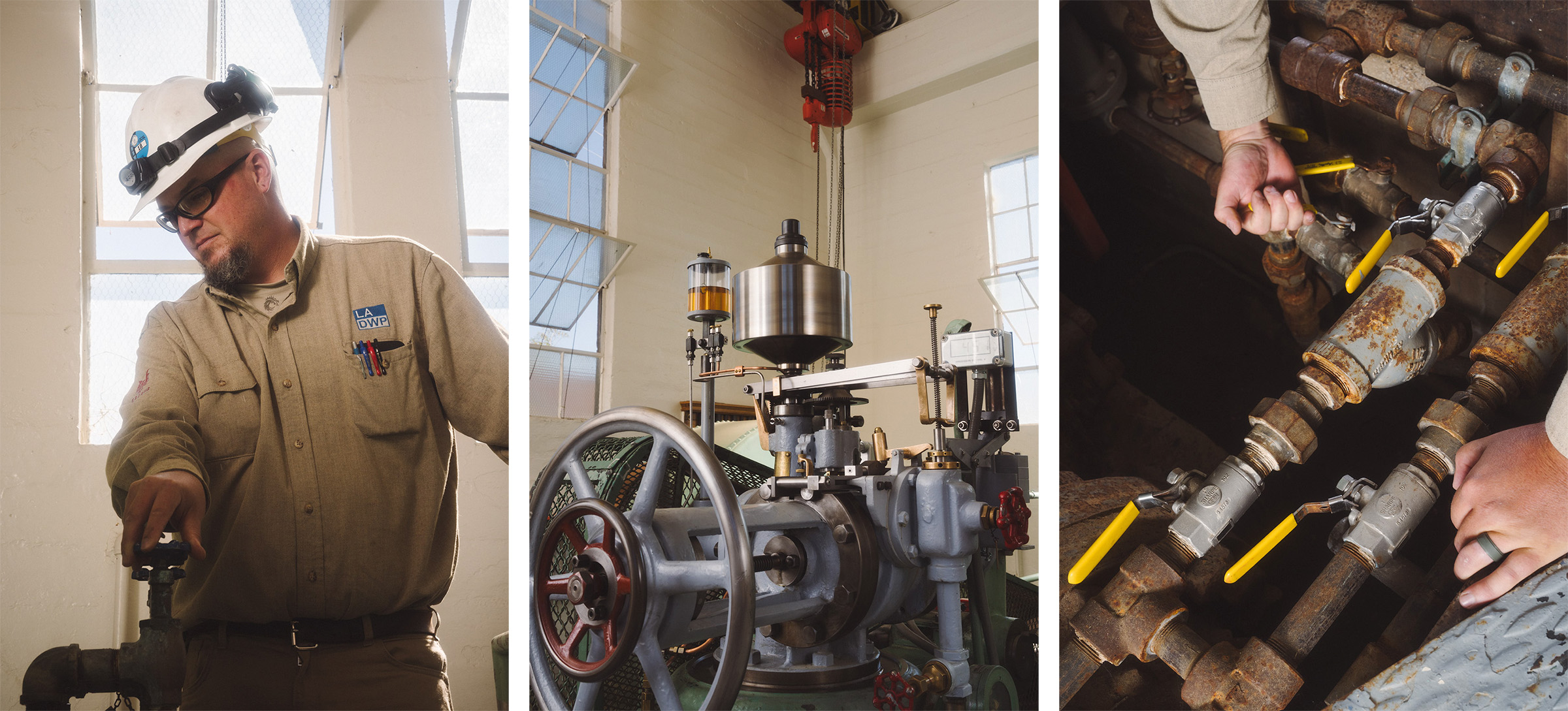

In summer 2024 photographer Brandon Tauszik documented Los Angeles’s 400-mile network of aqueducts and hydropower plants, some dating back more than a century.

Story by Ben Seal.

Water and Power

Could a century-old aqueduct point the way to Los Angeles’s clean energy future?