In 2005 a proposal to build a 17-story high-rise on six acres in the bedroom community of Ambler, Pennsylvania, touched off a firestorm of controversy among its 6,000 residents. A vocal contingent lambasted the plan, arguing that the height of the tower and number of units would add to traffic congestion, place undue strain on public services, and otherwise tarnish quality of life in the borough.

Such a story would be unremarkable in most of small-town America, but in Ambler there is another concern, one mixed into the soil. For three-quarters of a century the town was known as the asbestos-manufacturing capital of the world. At the site of the proposed tower and beneath dense vegetation lay 195,000 cubic yards of dun-colored dreck rising 25 feet above the surrounding ground. The site had for decades been used as a dump for asbestos-containing material. Kane Core, the high-rise’s developer, was unable to allay fears that construction would kick up asbestos dust—a potent carcinogen when inhaled—and so abandoned the project by year’s end.

The ad-hoc group Citizens for a Better Ambler played a leading role in drumming up opposition to the high-rise. With that proposal killed, the group set its sights on cleaning up the polluted Kane Core parcel and two neighboring contaminated plots. Following an aggressive campaign by the group, in 2009 the Environmental Protection Agency (EPA) designated the combined 32 acres a Superfund site, qualifying the property for federally funded and supervised cleanup and a long-term remediation plan. It’s the second such site for a town that is roughly three-fifths the size of Central Park.

For more than a hundred years Ambler has lived with asbestos, reaping both reward and anguish. The rise of asbestos as a “miracle mineral” built and sustained the town for generations; its fall brought the town to its knees. Ambler’s future will be built in part on an irony: the EPA, whose actions in the 1970s helped destroy Ambler’s economy, has become a player in its revival. But safety is never absolute, and the question Ambler’s residents now face is how safe is safe enough.

Making Ambler, Making Asbestos

Richard Mattison was born in 1851, the son of a Pennsylvania Quaker farmer. He went on to earn top honors at the Philadelphia College of Pharmacy and the University of Pennsylvania’s medical school. During his years at pharmacy school Mattison befriended the wealthy Henry Keasbey, who provided the necessary capital to jump-start Keasbey and Mattison Company (K&M) in 1873. K&M developed several patent medicines—chemical cocktails often with fanciful names and equally fanciful claims—that became best sellers, the most famous being Bromo Caffeine, for treating anxiety, and Alkalithia, for treating rheumatism.

The story has it that Mattison’s interest in asbestos, the mineral that would make him one of the Gilded Age’s nouveau riche, was based on chance. In the 1880s, after experimenting with several minerals and chemicals, including milk of magnesia, Mattison hit the jackpot when he found that mixing magnesium carbonate with asbestos produced an insulation fabric that could be wrapped around steam pipes and so save home and building owners on fuel costs. Mattison’s professional passion gradually shifted to devising and adopting every possible use for asbestos.

When Mattison passed through Ambler for the first time in the early 1880s, the town was in a slump. Grain milling had once been the lifeblood of the local economy, but the arrival of a railroad station in 1855 allowed farmers to send their grain by freight to cities, such as nearby Philadelphia, where large food distributors already offered grinding services. That newfound efficiency devastated the town. By 1880 the mills had either closed or were operating at a loss. The same fate befell Ambler’s sawmills and its silk and wool mills, the latter undone in the 1870s when fringed shawls fell out of fashion.

In Ambler, Mattison discovered the perfect elements for his empire: a steady supply of spring water, a railroad that could deliver asbestos from mines up in Quebec, and a rich supply of limestone nearby for medical ingredients and for building. In 1882 Mattison and Keasbey relocated their company to the feeble town and began transforming it from a collapsing agricultural outpost into a powerful industrial machine that would earn Mattison the sobriquet “Asbestos King.”

The Miracle Mineral

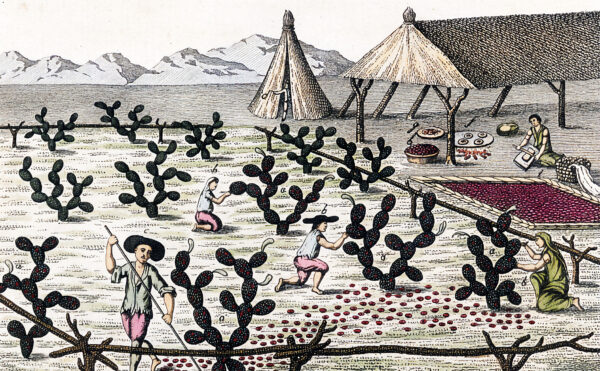

Both the Romans and the Greeks used asbestos—a family of silicon- and oxygen-based fibrous minerals whose combination of strength, fire resistance, softness, and pliability made them highly desirable. The widespread commercial use of asbestos began only in the 1860s after New York–based building contractor Henry Ward Johns came up with flame-resistant tar paper. The roofing material proved invaluable in preventing building fires, a widespread problem in densely settled cities. In the 1870s the discovery and development of asbestos mines in Quebec enabled large-scale production of asbestos fiber, meeting a growing demand for its use as an insulator. Asbestos was spun into cloth and wrapped around boilers on ships and on steam locomotives; it was turned into oven mitts and protective aprons and coats. Ultimately, asbestos was used in an estimated 3,000 different products, from chalkboards to floor tiles to plaster.

In 1896 Mattison built the nation’s first asbestos textile plant in Ambler. Its output was prodigious. In addition to manufacturing insulation for power-generating boiler houses and steam locomotives, the factory produced fireproof curtains for homes and theaters and brake linings for a new generation of faster automobiles in which asbestos replaced fast-wearing leather. But the company’s most lucrative product was its asbestos-cement fireproof roof shingles, which Mattison proclaimed in advertisements would result in a roof that “outlasts the building, without paint or repairs.” By the turn of the century sales from asbestos products outperformed those of the company’s pharmaceuticals. In 1906 Mattison bought a 120-acre asbestos mine in Quebec to meet demand for chrysotile, a form of asbestos whose flexibility was ideal for weaving into textiles.

Asbestos and patent medicines made Mattison fantastically wealthy. To satisfy his lifelong love of Gothic architecture, beginning in the mid-1880s Mattison arranged for the passage of stone artisans and laborers from southern Italy. These men built not only his turreted manor home on a 400-acre estate that he christened Lindenwold but also the residences for all of Mattison’s employees. He kept rents cheap for his employees and salaries low. Mattison owned the borough bank and all of Ambler’s utility companies, and his money funded construction of the town’s library and opera house.

K&M’s success continued throughout the early 1900s. During World War I the company supplied insulation for steamships, brake pads for army vehicles, and strap linings for soldiers’ helmets. But the stock market crash of 1929 put an end to the Asbestos King’s reign. Not long before the crash, Mattison had bought Keasbey’s interest in the company by handing him a $4 million lump-sum payment. The timing couldn’t have been worse: the crash in October left him without the means to sustain operations at his factories in Ambler and elsewhere. In 1931 Mattison’s creditors removed him as K&M president. The king vacated his castle, let go of most of his 100-plus estate staff, and moved into one of the executive mansions. In 1934, two years before Mattison died, the company he founded was sold to the British asbestos-manufacturing behemoth Turner and Newall.

K&M continued to make asbestos products. With the onset of World War II demand soared for insulation and fireproof material for navy ships, army jeeps, and other combat-related paraphernalia. The need for these materials was so great that authorities prohibited all non-essential asbestos use. In the economic boom that followed the war, new construction across the country sustained demand. As the industry held steady, so did Ambler.

The High Price of Asbestos

I visited Ambler several times in fall 2014. One of the residents I met was Salvatore Boccuti, the grandson of Italian immigrants who settled there in the early 1900s. Seventy-three years old at the time of our meeting, Boccuti came of age during the 1950s and 1960s, and he remembers Ambler being like any other thriving town. “Weekends were fantastic around here,” he says of downtown. Clothing stores and jewelry shops would draw in customers from neighboring townships. “We used to have cops directing traffic because the crowds were so heavy.” Friday-night football games at the high school were well attended. The Feast of St. Francis of Assisi each October 4 brought the Italian community together with pasta, parades, and fireworks.

There was, of course, another shared experience—asbestos. Factory workers, mostly men, were exposed to tremendous amounts of the mineral, and in its most lethal form: dusty, airborne fibers. Reports of working conditions at asbestos plants across the country describe almost nonstop contact with the mineral. Workers mixed raw asbestos fibers from burlap bags into cement slurries before they pressed, dried, and cut the hardened mass into shingles. A similarly noxious environment affected those producing asbestos piping insulation: magnesium carbonate was mixed with asbestos in large tanks, then the combination was molded and pressed into various coverings. The worst conditions were found in the textile plant. After beating raw asbestos by hand to open up the fibers, workers fed them as long strands into carding machines, where they were twisted and spun into yarn for use in the manufacturing of gaskets, electrical insulation, brake linings, and other products. Exhaust fans disrupted the carding process, decreasing the quality of the yarn, so these areas were often not well ventilated.

Carol DiPietro grew up in Ambler, and her mother was a secretary for K&M during the 1940s. She told DiPietro about walking into the factory and seeing “all the asbestos fibers floating in the air. When she came back into her office, she used to have to brush her suit off.”

Eighty-three-year-old Victor Romano recalls factory workers not being too concerned about inhaling the mineral. “Once in a while, you would see a guy that would have a handkerchief over his face, over his mouth, but they didn’t have respirators,” he says. “You just didn’t think about it, and you didn’t know.” Men returned home with their soiled clothes, and wives would launder them. Homes adjacent to the enormous piles of leftover waste—long known as the “White Mountains”—were inundated with dust that collected on windowsills and porches and left a thick film on cars.

Kids played on the White Mountains. Jack Kettner, a friendly, burly man in his late 50s, grew up in Ambler and lives within a couple of blocks of the White Mountains. “There were walkways along the piles, and we used to run along them and throw shingles at the boys from West Ambler—sort of like a sham battle,” he says. The kids would try to avoid falling into the quicksand-like, white-purplish slurry that formed in the middle of the mountain after rain. (The EPA’s Jim Feeney, who now oversees the site’s upkeep, says the slurry was composed of calcium carbonate, magnesium carbonate, and asbestos waste left over from insulation manufacturing at the nearby factory.)

There were walkways along the piles, and we used to run along them and throw shingles at the boys from West Ambler—sort of like a sham battle.

“You knew you weren’t supposed to be hanging out there,” Henriquetta, Kettner’s sister-in-law, says. “A lot of people in town ended up dying from asbestos.”

Several people I met during my visits had lost family members to asbestos-related illnesses, including 60-year-old Sharon Cooke Vargas, who lost both her father and her grandfather to mesothelioma. Vargas has been hired by the University of Pennsylvania to help study the town’s history.

Why some get sick from inhaling asbestos fibers while others escape seemingly unscathed is still the focus of intense research, though the potential dangers have long been known, even if not always publicly acknowledged.

Asbestos-related deaths were first noted in the early 1900s. In the 1920s the medical establishment recognized one of asbestos’s hallmark diseases: asbestosis, a chronic, sometimes fatal illness where asbestos fibers scar lung tissue and make breathing difficult. Throughout the 1930s and 1940s, British and German pathologists gradually solidified the link between asbestos and lung cancer.

Asbestos companies also conducted their own investigations and sometimes tried to suppress inconvenient results. In the early 1950s Richard Doll, an epidemiologist working with K&M’s owner, Turner and Newall, found that those exposed to asbestos for 20 years or more were 10 times likelier to develop lung cancer than the general population. Doll and John Knox, who as Turner and Newall’s medical officer had collected the epidemiological data, attempted to publish their findings but were blocked by the company’s directors. Doll eventually published under his own name in 1955, but not before Turner and Newall attempted to cajole the medical journal editor into rejecting the paper.

By the end of the 1950s mounting research made the connection between asbestos exposure and lung cancer impossible to ignore. At the same time, another cancer caught the public’s attention: mesothelioma. This almost always terminal cancer develops in the mesothelium, the membrane that lubricates the body’s cavities and the outer surfaces of most of the internal organs. It’s most commonly discovered in the mesothelium of the lungs. Mesothelioma was a rare disease in the 1940s, but by the late 1950s it gained notoriety when researchers discovered it in epidemic proportions near asbestos mines in South Africa. The reputation of the miracle mineral was further tarnished in the 1960s when a report in the British Journal of Industrial Medicine showed that people who simply lived near an asbestos factory or who worked in an asbestos-insulated building were at an elevated risk for developing mesothelioma.

Vargas believes mesothelioma deaths of Ambler’s factory workers have historically been undercounted. Many who lived in factory housing in 1930 would later have lung disease listed as their cause of death. “A good number of them probably died from mesothelioma,” she says. A 2011 study released by the Pennsylvania Department of Health backs up her suspicions. It analyzed cancer diagnoses from 1992 to 2008 and found the rate of mesothelioma for Ambler residents 3.1 times higher than for those in the rest of Pennsylvania, a state with one of the highest mesothelioma rates in the country. The report emphasizes that the increased rate is likely due to previous asbestos exposure in the factories.

To this day the only known cause of the disease—diagnosed in roughly 3,000 people annually in the United States—is asbestos inhalation. There is no adequate method for detecting mesothelioma in its early stages, no clear-cut genetic blueprint to determine susceptibility, and no effective cure.

Saving People, Killing a Town

For almost a century asbestos manufacturing had been an economic mainstay for Ambler, but in the 1970s the abundance of evidence of the mineral’s toxicity led the EPA to curtail its use nationally. For the agency, saving lives meant killing off an enterprise that had sustained Ambler’s families for generations. These actions would lead to years of economic decline for the town.

Beginning in 1973 the EPA, under the auspices of the Clean Air Act, stopped the sale of asbestos-based insulation spray; in 1975 the agency outlawed solid asbestos insulation that was prone to crumbling. The 1989 Asbestos Ban and Phaseout Rule took most remaining asbestos products off the market. In 1991 the U.S. Fifth Circuit Court of Appeals struck down most of the 1989 order, citing insufficient evidence for a complete ban and the EPA’s failure to adequately consider alternatives. Nevertheless, asbestos products have nearly disappeared from the domestic marketplace. (Some asbestos-based products, such as brake pads and roofing material, are still available.)

By 1974, the year further dumping was banned, Ambler’s White Mountains contained more than 1.5 million cubic yards of asbestos waste spread over 25 acres. One asbestos plant shuttered in 1974; another, Nicolet Industries, continued to manufacture gaskets and construction products until it closed its factory in 1987. That same year, the company filed for Chapter 11 bankruptcy, citing the 61,000 asbestos-related lawsuits that had been brought against it since 1978. (By 2010 asbestos-related lawsuits played a role in the bankruptcies of nearly a hundred corporations, making it the longest-running mass tort in American history.)

From 1973 to 1993 the EPA oversaw a variety of remediation efforts at the White Mountains, which were renamed the Ambler Asbestos Piles and designated a Superfund site in 1986. The asbestos-manufacturing companies paid to grade and cap the piles with soil, install erosion and sedimentation control, secure the perimeter with fences and locked gates, and post warning signs. In time a dense stand of trees grew over the site.

Without its asbestos factories downtown Ambler hollowed out through the 1980s and much of the 1990s. On Butler Avenue, Ambler’s main drag, old mom-and-pop stores were boarded up and Section 8 housing took over upstairs apartments. Foot traffic was nearly nonexistent, except when it led to the growing number of dive bars, says longtime resident Bernadette Dougherty. “Then we started to get more drug problems.”

Some attribute the blight largely to the collapse of the asbestos industry, while others include the exodus of law firms and health care−related companies as well as the rise of new shopping malls in neighboring towns that drew retail business away. The abandoned factories lining the railroad deteriorated, rusting over with asbestos-crusted floors. “It was pretty bleak,” Boccuti says.

Ambler, Reborn Again

By the late 1990s an upswing began. The Ambler Main Street program, formed in 1992 as part of a national effort to revitalize former industrial towns, was the initial catalyst. Dougherty, the program’s manager from 1996 to 2007, focused on convincing people to invest in and support businesses in Ambler. In 1998 Act II Playhouse opened on Butler Avenue, drawing in local theater enthusiasts, followed by a pub the year after. In 2003 the historic 1920s Ambler Theatre reopened. “Suddenly Ambler was starting [to become] a destination place rather than just a drive-through place,” says Ambler councilman Frank DeRuosi.

As I walked around downtown on a Friday night in October, I found the town’s revival continuing. A few boutiques have settled in, along with high-end salons and a psychic. Forest and Main Brewing Company, which occupies a cozy, yellow Victorian, draws a mixed crowd of college-aged kids and young professionals. An upscale steakhouse and Mexican and Indian diners were all hopping. Girls in pink ballerina outfits shuffled out of the Addicted 2 Dance studio that now operates behind Act II Playhouse, where nattily dressed patrons filed indoors.

Suddenly Ambler was starting [to become] a destination place rather than just a drive-through place.

Kane Cheung, owner of a new business that combines painting lessons and socializing, grew up in the area and graduated from nearby Wissahickon High School in the mid-1990s. Back then he would just pass through the downtown, never stopping. “There was nothing,” he says. After living in New York City and Philadelphia, Cheung recently returned to the area and found it drastically changed. The streets were clean, shops had opened and crowds were coming, especially on Friday nights and weekends.

Ambler’s borough council is now keen on redeveloping the former K&M factories that hug the regional rail line cutting through the southern and western edges of town. These properties are within walking distance to downtown and the train station, which offers a straight shot to central Philadelphia. Construction has begun, including a three-story townhouse development, which sits across the street from the brick-terraced house of Kettner, the man who used to play on the White Mountains as a kid. “It’s better than looking at a gutted factory,” Kettner says of the new development, noting that younger people and families have taken to it.

The Ambler Boiler House, built by Mattison in 1897, was left vacant when K&M was dissolved in 1962. Its towering smokestacks once powered the town, but the building gradually became a visible reminder of the community’s decline, with its missing roof, blown-out windows, and asbestos-contaminated rubble scattered inside.

In 2011 remediation began with the help of low-interest loans from county and federal agencies, including the EPA’s Brownfields Program. Crews hauled out asbestos-laced plaster insulation that once lined the inside of the brick boilers. A key safety requirement throughout the removal process, says John Zaharchuk, president of the company transforming the Boiler House, was keeping the environment wet. To remove the residual asbestos, the entire building was power-washed, with the dirty water treated and then disposed of in a sewer that leads to a wastewater treatment plant.

In all, the renovations cost $16 million, and the price tag shows. The Boiler House is powered by geothermal energy, dressed in high-efficiency glass, and topped with a reflective roof system containing solar panels. The building where laborers once shoveled coal into boilers is now 97% occupied by a civil engineering firm, a brand management and marketing company, two software development companies, and a law firm. Its transformation represents the borough’s successful and ongoing transition from an industrial economy to a service-oriented one.

Zaharchuk isn’t finished with Ambler. His next proposed development is directly across from the Boiler House, on the site of a former K&M factory. The proposed project, a four-story, 115-unit, luxury apartment complex named Ambler Crossings, is in line with the borough’s vision of transit-oriented development. For now the site remains an overgrown pile of concrete ruins, with crumbly asbestos underneath.

An Uneasy Solution

Asbestos waste is still buried and scattered throughout many of the sites of Ambler’s old factories. Uprooted trees, burrowing animals, and flooding of local waterways threaten to bring it to the surface. The EPA has spent decades and more than $25 million trying to keep these threats under control at Ambler’s two Superfund sites, primarily by burying the waste, layering it with a synthetic fabric to prevent upward migration, capping it all, and stabilizing the banks of the waterways.

The Ambler Asbestos Piles site was removed from the Superfund list in 1996, but because asbestos is still present, the EPA reviews the property every five years. The EPA is scheduled to complete the initial cleanup phase of the Superfund process at the other site, named BoRit, in 2015. Most longtime residents expect that capping the asbestos will become the agency’s long-term remedial plan for BoRit, the same approach taken with the Ambler Asbestos Piles.

Many people seem content with these efforts, but a vocal group is not. One critic of the capping method is Sharon McCormick, who serves on the BoRit Community Advisory Group, which represents the interests of nearby residents, businesses, and nonprofits. She has involved herself in every asbestos-related controversy since the high-rise squabble in 2004, when she joined Citizens for a Better Ambler, which had played a leading role in drumming up opposition to the Kane Core high-rise. Afterward, she lobbied the EPA to declare the BoRit area a Superfund site, which happened in 2009. In 2014 she rode an asbestos-focused platform to a seat on the borough council. She is arguably the most outspoken person in Ambler in challenging the long-term adequacy of the EPA’s soil-capping approach for commercial or residential developments.

On a muddy Saturday in October, McCormick, an energetic 50-year-old, took me to the 25-acre Ambler Asbestos Piles site, situated across from a row of homes. One of the houses was once the home of 84-year-old Catherine Palfrey, who recalls seeing clumps of asbestos waste in her family’s backyard. “I used to play with it like it was snow,” she told me. These days a basketball court and a jungle gym, both with kids at play, are separated from the Ambler Asbestos Piles site by a fence with signage that reads “Caution: Asbestos Waste Disposal Site. Do Not Create Dust.”

The waste here is piled in steep slopes—the highest peak is more than 90 feet tall—and trees cover them. Along a trail that borders the site, McCormick picks up fragments of shingle and piping. As we edge closer to the slopes, brown topsoil gives way to ashen-colored silt made up of spent calcium carbonate and magnesium carbonate, along with lesser amounts of asbestos. “If the hard stuff can come out,” McCormick says, raising a shard of shingle, “that means the friable stuff, microscopic fibers, can be flushed out too.” A short while later we discover a few of what the EPA’s on-scene coordinator, Eduardo Rovira, says can be a problem: groundhog holes.

McCormick has repeatedly requested air and soil testing for the Ambler Asbestos Piles, but without any success. “You have children who play 15 feet away from that fence,” she says. “Children trespass behind that fence and walk on the piles.” McCormick’s is the loudest voice in town, but her arguments are backed by several residents.

The EPA’s Jim Feeney, remedial project manager for the Ambler Asbestos Piles, told me that air samples haven’t been taken at the site since 1988, but notes that air sampling is not required “without the observation of visible dust emissions or a specifically identified potential source.” Air tests conducted in 2010 and 2011 on the periphery of the BoRit site, which lies across the street from the Ambler Asbestos Piles, showed no signs of the fiber.

At the BoRit site trees were removed because uprooted trees may bring asbestos to the surface. On the Ambler Asbestos Piles, the policy is different because the EPA views the risks and benefits differently. Trees stabilize the steep slopes, Feeney says, and adds that any uprooted ones will be removed. Feeney also says the asbestos contained in the silt of the Ambler Asbestos Piles site is unlikely to move far through the chalky material.

The EPA has only a short list of remediation options, which apart from soil capping is currently limited to trucking out asbestos or melting the waste into glass. Both alternatives are exorbitantly expensive and pose their own environmental and health risks.

The Future

Last year the University of Pennsylvania, in partnership with other institutions, received funding from the National Institute for Environmental Health Sciences to jump-start several investigations, from determining the soil’s effectiveness in containing asbestos to evaluating a fungus’s ability not only to stabilize soil but also to break down asbestos fibers, rendering them nontoxic. Another study aims to develop treatments and a blood-based diagnostic tool for mesothelioma, while yet another is looking into genetic predispositions to the disease.

Fox Chase Cancer Center’s Joseph Testa, the researcher working on genetic predispositions, says that as a general rule there is no safe level of exposure. “Any exposure to asbestos is potentially carcinogenic,” he says, while also emphasizing that mesothelioma is a relatively rare disease. Of the many asbestos workers who inhaled the mineral every day for years, only a minority went on to develop mesothelioma.

Safety is less of an absolute state and more about balancing risks. And in Ambler perceptions of risk lie on a spectrum. Council member DeRuosi thinks the EPA’s soil-capping method is currently the most sensible option. “Ultimately, I would love to see [the asbestos waste] removed because I think people still have that image of Ambler in their heads, that it’s a Superfund site. But in removing [the waste] you’re just creating a bigger problem.” Trucking out the waste would kick up a lot of dust. But as it stands now, he says, “Background exposure to asbestos, such as what we have now, poses less of a threat.”

Susan Curry might settle for what the EPA is doing, just more of it. She lives about a mile away from the BoRit site, a distance she believes still puts her at risk for asbestos exposure. While not entirely sold on the soil-capping option, if that becomes the final remediation, she wants to see it doubly enforced. “If they put that mat [geotextile], then put soil, and then put another mat and another layer of soil, I’d be a lot more at ease.”

Vargas, whose father and grandfather died from asbestos exposure, is waiting on the EPA’s proposed long-term remedial plan for the BoRit site before casting judgment. As for South Ambler, where the factories once stood and now the site of the renovated Boiler House and the slated transit-oriented development, Vargas wouldn’t take a job there if one were offered. “They’ve got mounds of stuff on top of the asbestos to capture it,” she says. “That may be, but it’s not for me. I just don’t feel comfortable working in that area.”

Justin Zimmerman takes a more relaxed approach. He is part of the younger set that has moved into Ambler in recent years. Last summer he and his wife relocated from Delaware into a house across the street from the planned Ambler Crossings apartment complex. Zimmerman has no concerns with the proposed construction; in fact he welcomes it. “I’d like to see something other than a demolition job and overgrown trees,” he says, looking out from his front porch.

With 73 years under his belt, Boccuti takes a long view of things. “Keasbey and Mattison built this town, and we’ve lived with asbestos all our lives,” he says. “We’ve had some hardships, but a lot of the people I knew growing up are still here. I’ve been in the same house for 61 years. It’s just a nice little town, and I’m glad to see it making a resurgence.”