One night in November 1938 a palpable silence fell over the north ballroom of the Stevens Hotel in Chicago. Arthur Edmund Pew, Jr., vice president and research head of Sun Oil Company, had just finished presenting a paper at the 19th Annual Meeting of the American Petroleum Institute. After a few moments applause erupted followed by a few questions, though most of the audience sat silent, absorbing what they had just heard.

Pew had presented a paper with the uninformative title of “Catalytic Processing of Petroleum Hydrocarbons by the Houdry Process,” the contents of which influenced the future of gasoline production and the course of World War II.

At that time gasoline was obtained through thermal cracking, an inefficient heating process where only about 25% of the crude oil converted to gasoline, leaving behind a tarry waste fit only for road oil and roofing tar. Increasing gasoline consumption—despite the Depression—added to pressure on oil companies, as did demand for better octane ratings for thirsty high-compression engines.

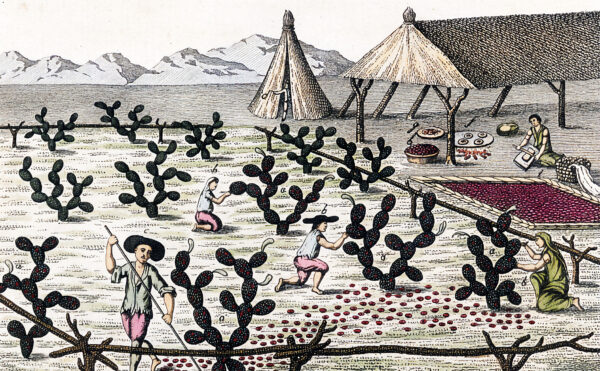

Europe had faced fuel shortages as early as the end of World War I. At the time, many worried that within a few years the world’s oil supply would be depleted. In response, Eugene Jules Houdry, a French mechanical engineer with a passion for racing cars, decided to turn lignite, a low-rank, brownish-black coal, into gasoline.

Although France lacked oil, lignite was readily available, and with the support of the French government Houdry and his syndicate developed a demonstration plant in 1929. While the process proved successful, it was also expensive; the government withdrew its support, and the plant shut down soon after.

Undaunted, Houdry continued his research, discovering that a porous, silica-alumina material called fuller’s earth— essentially activated clay—worked as a catalyst to convert the oil derived from lignite into a gasoline-like substance. He then used the catalyst to convert vaporized petroleum to gasoline. This advance intrigued many in the oil business, including H. F. Sheets of the Vacuum Oil Company, who invited Houdry to the United States to demonstrate the process on a larger scale.

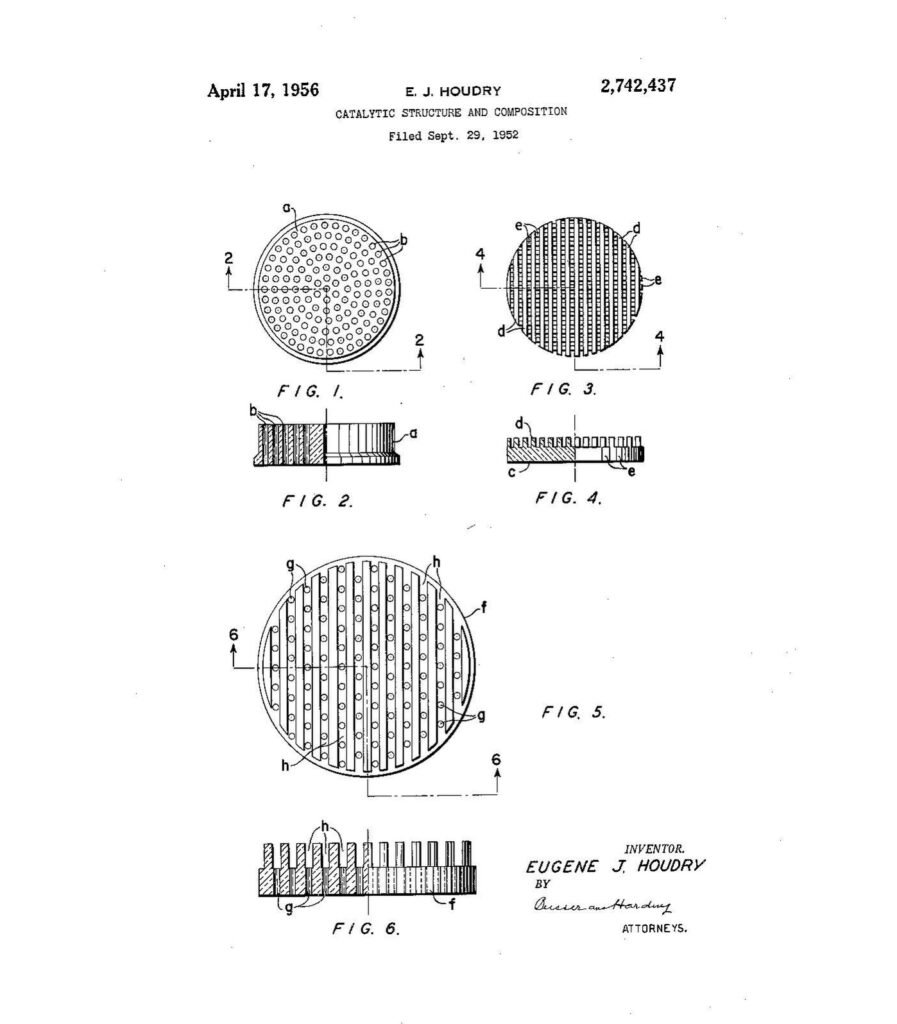

Patent drawing, filed Sept. 29, 1952.

Houdry arrived at Vacuum Oil in Paulsboro, New Jersey, in October 1930. The next year Vacuum Oil merged with Standard Oil of New York (Socony). Although Vacuum successfully scaled up a 20-barrel-a-day model to a 200-barrel one, the merger coupled with the Great Depression left Houdry’s process effectively orphaned by 1933. Vacuum kept its one-third interest but allowed Houdry to seek backing from others.

While many oil companies praised the process, none provided funding. Clarence Thayer of Sun Oil Company, who worked closely with Houdry, likened Houdry’s personality to that of a “bulldog” because he never gave up. Houdry came from a wealthy family and used his own money to continue promoting the process. Later that same year Houdry met with Sun Oil’s president, J. Howard Pew, and its vice president for refining, Arthur Pew, Jr. After this meeting Sun Oil and Socony-Vacuum signed a joint agreement with Houdry to further develop the process. Houdry referred to the day of the meeting as “the most beautiful day” of his life.

After modifying Houdry’s techniques, in April 1936 Socony-Vacuum transformed a thermal-cracking unit at Paulsboro into a unit that used the Houdry process. In just under a year a new unit was processing 15,000 petroleum barrels a day. At the 1938 meeting of the American Petroleum Institute industry insiders sat up and took notice.

Aside from the growing demand for gasoline, the effect of the Houdry process on octane ratings ultimately guaranteed its commercial success and later proved crucial to the war effort. During the first two years of World War II, 90% of aviation gasoline came from Houdry plants, giving British planes a decisive edge over their German counterparts during the 1940 Battle of Britain. The higher-octane rating provided Allied planes with a 15% to 30% increase in power during takeoff and while climbing when compared with German planes.

Houdry launched what became known as the “catalytic revolution.” Seventy-five years later, Houdry’s technology is still used. Although the catalyst and the productivity of the process have undergone changes, the process itself is still essentially the same.