In 1905, in France, chemist Jacques Brandenberger spilled wine on a tablecloth and wished for a material that could be wiped clean with a wet cloth. Swiss-born Brandenberger spent the next several years perfecting a transparent, moisture-repellent film he named cellophane.

In the United States, DuPont’s William A. Spruance recognized the commercial potential of Brandenberger’s plant-derived cellulose plastic: Whitman’s candy company was already using cellophane as a wrapping for its high-end line of chocolates. Spruance acquired U.S. production rights from Le Cellophane—the French owner of the cellophane process—intending to make commercial packaging material. DuPont, originally a manufacturer of gunpowder and explosives, had just entered into the plant-based plastics industry through its rayon manufacturing, and Spruance wanted his company to diversify further.

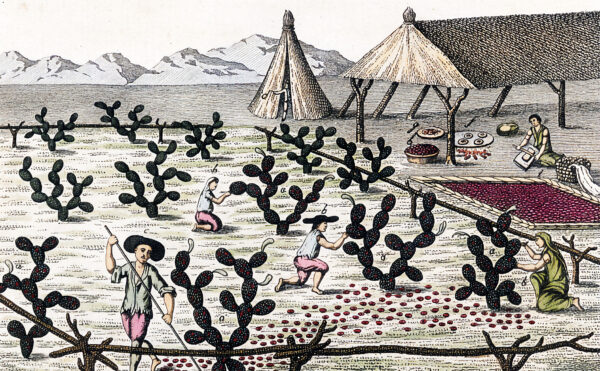

The cartoon above depicts “C-Day”—April 4, 1924—when the first cellophane was made in the United States. Among the personalities depicted is Brandenberger, or “No. 42,” shown in the lower center of the cartoon admiring the “Machine a’ pellicule” (or casting machine). Brandenberger had created the casting machine to transform liquid viscose into sheets of cellophane. Here he is exclaiming, “Ces Americains!”—which can be read as either a blessing or a curse. The reactions of his excitable assistant François (“No. 43”) would seem to point toward the latter interpretation.

DuPont had high hopes for “C-Day,” but in the lower left corner of the cartoon trouble is brewing. Crates of returns crowd the incoming door of the shipping dock, while a spider spins its web over the outgoing door. The trouble was in the cellophane: to the French, cellophane was just waterproof, meaning it would not dissolve in water, but it was not moisture resistant. Water vapor could penetrate the wrapping and spoil the contents within, be they Whitman’s chocolates or a head of Salinas Valley lettuce.

DuPont chemists William Hale Charch and Karl Prindle worked to turn this potential loser into a winner. Within three years Charch developed a nitrocellulose lacquer whose application made cellophane moisture-proof, allowing it to keep food fresher for longer. When the United States entered World War II, cellophane was classified as an “essential material,” used for the packaging of G.I. rations and making vapor-resistant “gas capes” (which inventive soldiers promptly used as rain gear).

In 1949 DuPont issued a commemorative booklet to celebrate 25 years of cellophane production in the United States. In addition to the cartoon it also contained an open letter written by Brandenberger. “Dear Friends,” he wrote, “Twenty-five years ago I travelled with my collaborators to Buffalo to start the first casting machine. Your organization helped greatly in this difficult task, and consequently, the starting-up period was not long.” He concluded with the words, “You have all my admiration for the great work you have accomplished in your country.” With that, a blessing was granted.

Correction: In the original text we spelled William Hale Charch’s name wrongly as Church. This version has the correct spelling.