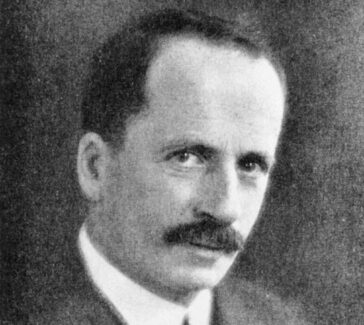

Leo Hendrik Baekeland

The Belgian-born chemist and entrepreneur Leo Baekeland invented Bakelite, the first fully synthetic plastic.

Colorful objects made of Bakelite—jewelry, telephones, radios, and billiard balls, to name just a few—brightened everyday life in the first half of the 20th century. Today these vintage consumer goods are prized by antique dealers and collectors.

A polymeric plastic made from phenol and formaldehyde, Bakelite was one of the earliest synthetic materials to transform the material basis of modern life. It was named for its inventor, Leo Hendrik Baekeland (1863–1944), who discovered the durable plastic in 1907. Baekeland’s inventive and entrepreneurial genius also propelled him into several other new chemical technological ventures throughout his life.

A Fortune from Photographic Paper

After completing his doctorate at the University of Ghent in his native Belgium, Baekeland taught for several years. In 1889, when he was 26, he traveled to New York on a fellowship to continue his study of chemistry; this same fellowship also allowed him to visit universities in England, Scotland, and Germany.

After the fellowship Professor Charles F. Chandler of Columbia University persuaded Baekeland to stay in the United States and recommended him for a position at a New York photographic supply house. This experience led him a few years later, when he was working as an independent consultant, to invent Velox, an improved photographic paper that could be developed in gaslight rather than sunlight. In 1898 the Eastman Kodak Company purchased Baekeland’s invention for a reputed $750,000.

From Shellac to Plastic

When friends asked Baekeland how he entered the field of synthetic resins, he answered that he had chosen it deliberately, looking for a way to make money. His first objective was to find a replacement for shellac, which at that time was made from the shells of Asian lac beetles.

Chemists had begun to recognize that many of the natural resins and fibers useful for coatings, adhesives, woven fabrics, and the like were polymers. Although it was still unclear what the molecular structure of polymers might be, chemists and others began to search for combinations of reagents that would react to form synthetic polymers.

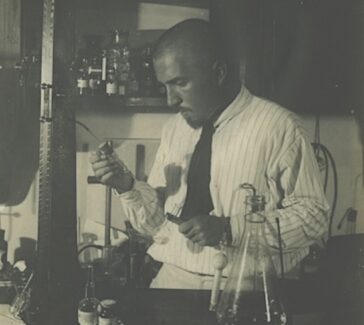

Baekeland investigated the reactions of phenol and formaldehyde, first producing a soluble phenol-formaldehyde shellac called Novolak, which never became a market success. Then he turned to developing a phenol-formaldehyde binder for asbestos, which at that time was molded with hard natural rubber.

By carefully controlling the pressure and temperature applied to an intermediate made from the two reagents, he produced a polymer that when mixed with fillers, produced a hard moldable plastic. Bakelite, though relatively expensive, was soon found to have many uses, especially in the rapidly growing automobile and radio industries.

Brightly colored objects made of dyed phenol-formaldehyde plastic, now prized by collectors, were in fact based on processes developed by German chemists and first introduced into the United States in 1927 by the American Catalin Corporation. But the Bakelite Corporation was quick to follow suit in producing such vivid plastics.

Baekeland retired in 1939 to sail his yacht, the Ion, among other activities, and sold his successful company to the Union Carbide and Carbon Corporation, now a subsidiary of the Dow Chemical Company.

You might also like

SCIENTIFIC BIOGRAPHIES

Nancy Chang

Born in Taiwan, Chang made the long trip to the United States to study at Brown University and then Harvard. She became one of the world’s most successful biotechnology entrepreneurs.

EDUCATION

Conflicts in Chemistry: The Case of Plastics

This role-playing simulation game asks students to consider the positive and negative aspects of plastics through research and debate.

DIGITAL COLLECTIONS

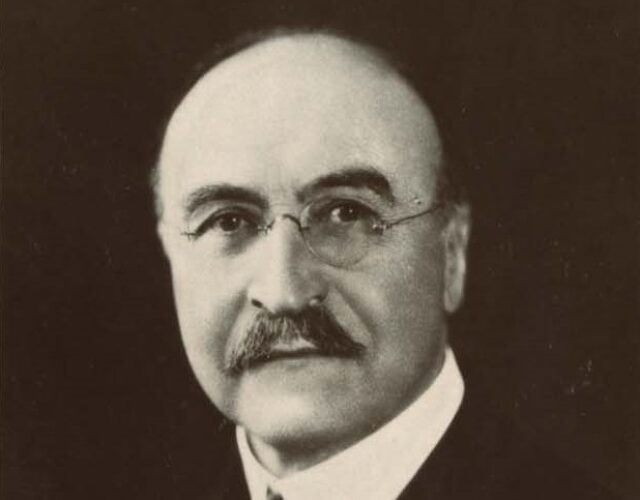

Oral History: Robert D. Kennedy

Interview with the American businessman who worked for more than 40 years at Union Carbide, including as CEO.