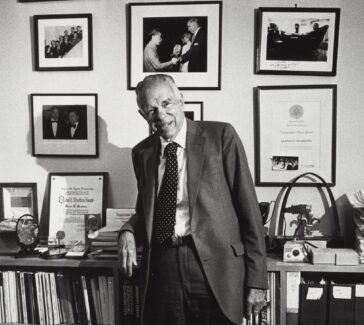

Eugene Houdry

The catalytic process for “cracking” petroleum molecules into the shorter ones that constitute gasoline was developed by Houdry, who also created an early catalytic converter for cars.

Earlier commercial processes for cracking petroleum were thermal processes, relying on heat rather than on catalysis. Because catalysts can reduce the pressures and temperatures needed for carrying out commercially useful reactions, they help reduce costs.

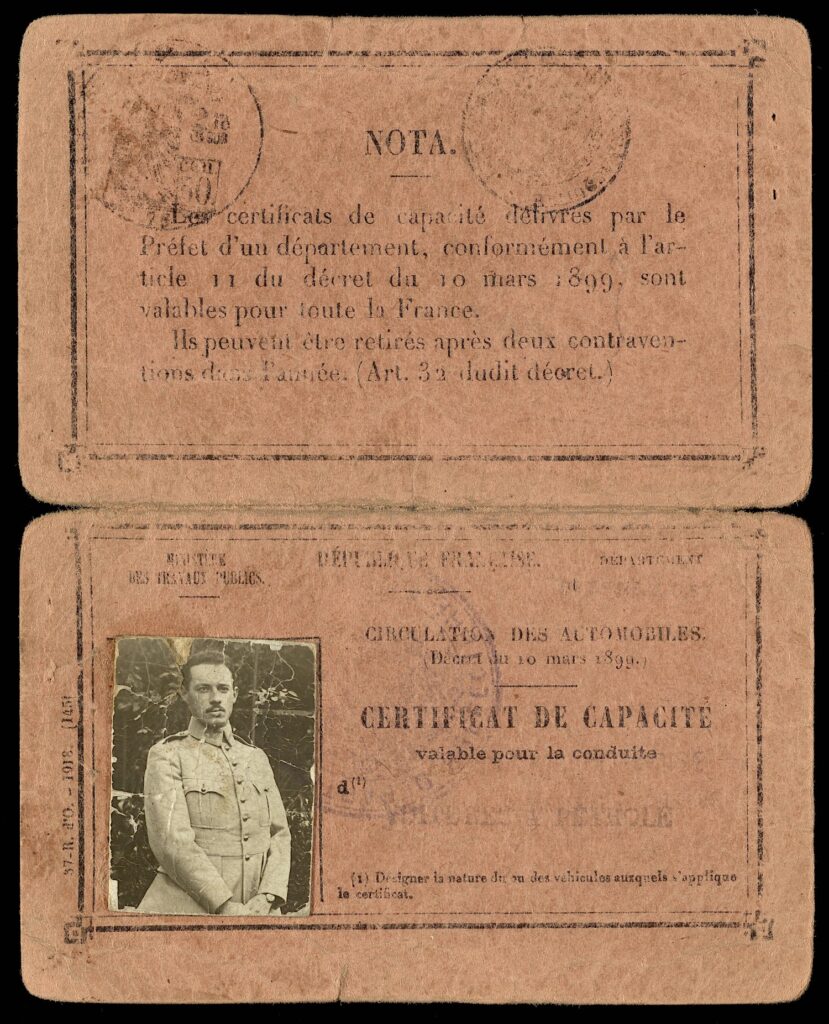

One of the first improvements in petrochemical production was the catalytic process developed by Eugene Houdry (1892–1962), who obtained a degree in mechanical engineering in his native France before joining the family metalworking business in 1911.

A Passion for Race Cars

After serving in the tank corps in World War I, for which Houdry received honors for extraordinary heroism in battle, he pursued his interest in automobiles (especially race cars) and their engines. On a trip to the United States he visited the Ford Motor Company factory and attended the Indianapolis 500 race. His interest soon narrowed to improved fuels.

Because France produced little petroleum—and the world supply was thought to have nearly run out—Houdry, like many other chemists and engineers, searched for a method to make gasoline from France’s plentiful lignite (brown coal).

After testing hundreds of catalysts to effect the hoped-for molecular rearrangement, Houdry began working with silica-alumina and changed his feedstock from lignite to heavy liquid tars. By 1930 he had produced small samples of gasoline that showed promise as a motor fuel.

High-Octane Fuel

In the early 1930s Houdry collaborated with two American oil companies, Socony Vacuum and Sun Oil, to build pilot plants. Oil companies that did not want to resort to the new additive tetraethyl lead were eagerly looking for other means to increase octane levels in gasoline.

In 1937 Sun Oil opened a full-scale “Houdry unit” at its refinery in Marcus Hook, Pennsylvania, to produce high-octane Nu-Blue Sunoco gasoline. By 1942, 14 Houdry fixed-bed catalytic units were bearing the unanticipated burden of producing high-octane aviation gasoline for the armed forces.

Birth of the Catalytic Converter

One limitation of Houdry’s process was that it deposited coke on the catalyst, which required that the unit be shut down while the coke was burned off in a regeneration cycle.

Warren K. Lewis and Edwin R. Gilliland of the Massachusetts Institute of Technology, who were hired as consultants to Standard Oil Company of New Jersey (now ExxonMobil), eventually solved this problem with great ingenuity and effort. They developed the “moving-bed” catalytic converter, in which the catalyst was itself circulated between two enormous vessels, the reactor and the regenerator.

Air Pollution and the Catalytic Converter

Houdry continued his work with catalysts and became particularly fascinated with the catalytic role of enzymes in the human body and the changes in enzyme-assisted processes caused by cancer.

About 1950, when the results of early studies of smog in Los Angeles were published, Houdry became concerned about the role of automobile exhaust in air pollution and founded a special company, Oxy-Catalyst, to develop catalytic converters for gasoline engines—an idea ahead of its time. But until lead could be eliminated from gasoline (lead was introduced in the 1920s to raise octane levels), it poisoned any catalyst.

In 1959 Houdry was awarded the Society of Chemical Industry’s prestigious Perkin Medal.