When Australian entrepreneur John Harrison invented a new kind of cement in the late 1990s, he expected manufacturers would adopt it quickly. Not only was concrete made from the new material strong and durable; it also readily absorbed carbon dioxide from the atmosphere. By contrast, production of traditional Portland cement, which the world has been using for the past 150 years, releases vast amounts of CO2 and is a major contributor to climate change.

Industrious and talkative behind a bushy, graying beard, Harrison had already succeeded in a number of businesses. He’d run a large accounting practice, invested in pharmaceutical manufacturing, operated a ferry, and owned a farm, where his frustration with rotting wooden fence posts led him to design and sell posts made of precast concrete. He immersed himself deeply in the science of the material, eventually developing a recipe for “eco-cement” based on magnesium rather than the calcium compounds in Portland cement.

Harrison smelled success yet again. He secured a global patent, won first prize at an inventors’ expo, appeared on national TV, and anticipated imminent mass production of his cement. “I thought people would want to license the technology and get on with it,” he says.

But the deals Harrison hoped for never materialized. Manufacturers spurned his product, contending it was more costly and less beneficial than he claimed. Another start-up came up with a suspiciously similar magnesium cement, spurring a bruising and expensive legal battle. He nearly went bankrupt. His wife died, and he became depressed. His experiences had moved from “euphoria and enthusiasm at the way the world treated me, down to feeling utterly miserable as to why is everybody kicking me and trying to steal from me. The world is unfortunately a hard place.”

It’s a lesson a number of cement scientists and entrepreneurs have learned over the past two decades. The cement industry is a leading source of greenhouse gases, accounting for an estimated 5% of global CO2 emissions, or about 1.4 billion metric tons a year. As alarm has mounted over the looming environmental and social impacts of global warming, a concerted effort has been under way to change production methods. Manufacturers have improved their plants’ energy efficiency and added different materials to their cement mixes to reduce the CO2 burden per ton produced. Yet total emissions have nonetheless continued to climb as demand has soared in China and India. For a variety of reasons efforts like Harrison’s to fundamentally change the chemistry of cement so it does not release so much CO2 have made little headway.

A Dawning Awareness

The difficulty of reducing emissions stems in part from the heavy fuel consumption integral to cement production. The basic process begins with the firing of limestone at 700°F or higher for several hours or even days. Mixing the resulting lime powder with water causes a chemical reaction that forms new limestone.

When humans began making lime mortars and plasters some 12,000 years ago, they developed bottle-shaped kilns to focus the heat and had to use at least a dozen cords of wood—about 1,000 cubic feet of solid fuel—to fire a single small kiln. “As human populations grew, large swaths of forests would be leveled to provide the wood for limekilns,” Robert Courland writes in Concrete Planet.

Two millennia ago the ancient Romans made extensive use of “hydraulic” concrete, building the Pantheon and other architectural marvels. The material is rightly celebrated for its remarkable durability, but it too required great volumes of fuel. The man-made Harbor of Caesarea in ancient Judea, the largest concrete project until the 20th century, required well over 60 million pounds of lime, which was produced by burning 100,000 to 200,000 trees. Courland says it was Rome’s great political power—specifically, its sway over a trio of well-forested states along the Danube River—that gave the builders access to enough timber to allow the harbor’s construction.

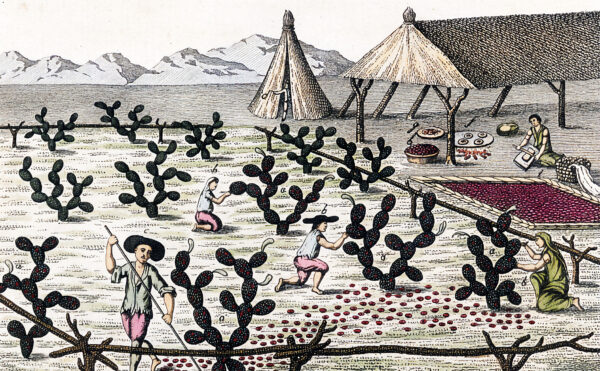

Centuries later the energy demands of making lime may have contributed to the collapse of a highly developed society. The ancient Maya produced masses of lime mortar so they could cover their pyramids with stucco and stunning bas-relief sculpture, burning about 15 trees for every cubic yard of lime they made. According to one theory the resulting deforestation led to soil erosion, agricultural decline, and finally the civilization’s disintegration starting around 800 CE.

Pyramid of the Magician in the ancient Maya city of Uxmal, in Mexico, 2010. Some scholars believe production of cement for Maya structures set off a chain reaction that led to the decline of the civilization.

While ancient mortar production was extensive enough to consume vast forests, it was a drop in the bucket compared with the modern cement boom that began in the early 19th century. British engineers rediscovered hydraulic cement, which they made by baking limestone together with clay. Cement makers subsequently realized if they fired the mixture at 1,450°F until it turned into hard lumps called clinker and ground those into a powder—which they called Portland cement—they could produce super-strong concrete.

Having run out of timber for fuel, the European cement industry switched to coal and coke, a form of cooked coal. Bottle-type kilns, which were slow and wasted heat, gave way first to shaft kilns and eventually to rotary kilns, which can run for a year or longer before being shut down for maintenance. Well into the 20th century technological advances in cement manufacturing were primarily driven by demand for greater output. The cost of kiln fuels was a lesser concern, and the environmental effects of their CO2 emissions didn’t register at all. That began to change in the 1970s when an oil embargo by Arab states caused dramatic spikes in energy prices. The urgent need to use fuel more efficiently helped usher in important innovations, such as precalciners, which use excess heat from the kiln to precook the cement mixture before the final firing.

The new focus on efficiency coincided with growing concerns about the warming of the earth, but it did not lead to a drop in greenhouse-gas emissions. More than half the CO2 put out by a cement plant comes not from burning coal but from the calcination process, in which limestone (calcium carbonate, CaCO3) is heated to drive off CO2, producing lime (calcium oxide, CaO). As nations and international organizations pushed for emission cuts, manufacturers responded by reducing the amount of lime in their cement mixes and adding more of other materials. The ancient Romans mixed a volcanic ash called pozzolana into their cement to make hydraulic concrete; cement companies now use industrial waste with properties similar to pozzolana. These include blast-furnace slag, a glassy rock left over from steel production, and fly ash from coal-burning power plants.

Producers have succeeded in cutting their emissions as much as 20% in recent years, from a ton of CO2 per ton of cement down to about 0.8 tons of CO2. Yet it appears the industry may be reaching the limits of what it can achieve with fuel efficiency and fly ash. Meanwhile, total CO2 emissions from cement have kept climbing as production increases. If the world wants to slow or stop global warming while continuing to use concrete, more radical changes are needed. Cement would need to be part of the solution to climate change rather than a major cause.

Using CO2 to Build

What if, instead of sending more CO2 into the atmosphere, cement could store it away? When conventional concrete hardens and cures, turning back into a form of limestone, it actually absorbs CO2 from the air. But the concrete can only absorb a portion of the gas released in the initial cement production—and even that takes decades.

One of John Harrison’s main selling points for his magnesium cement is that the concrete absorbs all of that CO2 in just a few months. But how about making a cement that emits little or no CO2 during production? Or a concrete that sequesters CO2 immediately? Or one that stores more than it emits in production, making it carbon negative?

These are daunting technical challenges, but a number of researchers have proposed at least partial solutions. One prominent innovator is Brent Constantz, a California scientist and expert on biomineralization who made his name inventing lifesaving medical cements for bone fractures. Several years ago he developed a process for making building cement using seawater and the waste CO2 emitted by power plants. According to Constantz, producing a cubic yard of his material eats up 250 pounds of CO2, whereas making the same amount of Portland cement releases 600 pounds of the gas.

What if, instead of sending more CO2 into the atmosphere, cement could store it away?

Tall and stocky, with round cheeks and a beaming smile, Constantz began his career far from the cement yard. As a graduate student he scuba dived and took submarines down to study the coral reefs of French Polynesia, and for his PhD thesis he grew coral skeletons in a test tube. “Biomineralization is the most esoteric-geeky subject probably on the planet, and most people don’t really pay much attention to it,” he said during a 2011 talk at Stanford University. But, he decided, “I really wanted to do something really important.” He learned about the huge costs and fatality rates of hip and vertebral fractures, realized that coral-inspired cements could work much better than the metal pins traditionally used to hold together broken bone, and started Norian, the first of several companies he would lead.

Later, when his oldest son was being treated for cancer, Constantz befriended some surgeons at the hospital and learned about the problem of calcified arteries, which often lead to amputations. Together they came up with procedures to clear the calcification and started yet another company. Before his son died, Constantz took him diving on a coral reef, and it occurred to Constantz that future children would never be able to see reefs because warming waters and acidification caused by climate change are killing them. Constantz could have retired, but he had “this aching desire to do something on the environment,” he recalled. He’d already formulated thousands of different cements in his career; once he learned about the huge carbon footprint of structural cement, it was simple to formulate one more that could be manufactured by combining seawater and waste CO2 and then to sell the idea to his venture-capitalist friends.

“It only makes sense to take CO2 to make structures,” he said in May 2010, as he sat next to former British prime minister Tony Blair at a conference in Sausalito, California. “We’re eliminating the problem of cement and the problem of CO2 coming from the combustion of fossil fuels for electrical power generation together at the same time.”

Unlike many green technologies his invention seemed like it might actually make the leap from the lab to the street. His company, Calera, attracted $180 million in venture-capital investment and drew wide acclaim. New York Times columnist Thomas Friedman praised the company in a column, and CNBC named Constantz one of the decade’s top 15 innovators.

Yet by later that year the wheels were already coming off the project. Constantz says his investors were banking on the establishment of a national carbon-pricing scheme, under which power companies would pay Calera to take away their waste CO2. But the U.N. Climate Change Conference in Copenhagen had collapsed the previous year without national commitments to cut greenhouse-gas emissions, and carbon pricing now seemed a distant prospect. Critics also questioned Calera’s environmental bona fides, noting it had to use electricity to produce a necessary alkali ingredient. Constantz stepped down as CEO, Calera sold off its cement plant, and the company refocused its carbon-extraction technology on manufacturing more profitable industrial chemicals.

Biomimicry seeks to replicate the attributes and mechanics of other living things to create innovative materials. Stony coral, photographed here, secrete calcium carbonate (the raw material of cement) to build a protective skeleton. Inventors have used this biological model to produce more effective and ecologically friendlier cements.

It turns out that marketing a new cement is really, really hard, even for an experienced, well-funded entrepreneur. In an interview, Constantz pointed out that testing the shelf life of a new mix and the durability of the resulting concrete takes years, and the high cost of the legal liability for a cracked foundation or collapsed bridge discourages risk taking among builders. Making cement is a lucrative business, and manufacturers are in no rush to fundamentally alter their production processes, never mind the looming threat of climate change. Having soured on cement, Constantz also argues that the much larger project of capturing and storing industrial CO2 emissions—including from cement plants themselves—will have far more impact than changing the way the stuff is made.

Making cement is a lucrative business, and manufacturers are in no rush to fundamentally alter their production processes, never mind the looming threat of climate change.

“Moving the industry away from Portland cement is, I guess, fathomable, but probably is never going to happen for a whole bunch of reasons,” Constantz said. “We’re literally decades away from any broad adoption of any new cement formulations. You know, me of all people, I love new cement. It’s what I’ve been doing most of my professional career. But in terms of practice, amongst the battles we have to fight, replacing Portland cement … I’d say it’s a long run for a short slide.”

A Rocky Future

Despite the challenges, a few companies are still trying to profitably produce cement that stores large amounts of CO2, typically by injecting the gas into wet concrete. CarbonCure Technologies of Nova Scotia collects waste CO2 from oil refineries and other facilities and adds it to a wet cement mix, which offsets up to 5% of the concrete’s carbon footprint. Rather than producing cement powder, the system manufactures bricks or ready-mix concrete, a paste made at a central plant and delivered to a job site in a truck.

Solidia Technologies of New Jersey has a cement fired at relatively low temperatures and later cured with CO2 gas. The company says its manufacturing process emits 30% less CO2 than Portland cement, and the resulting brick and precast concrete stores large amounts of CO2. On its own, however, the cement still isn’t carbon neutral.

Perhaps the most far-out alternative cement company with real prospects for success is bioMASON. It produces only brick but does so without a significant carbon footprint or any kilns whatsoever. The company’s cofounder Ginger Dosier traces her interest in making brick to her childhood growing up in Alabama. She loved getting her hands dirty, whether building sand castles or making mud pies, and was fascinated by seashells.

During graduate school for architecture her professor gave her a book on the concept of biomimicry, or copying nature. She became interested in naturally occurring calcium structures and, much like Constantz, in emulating the process of seashell and coral formation to create cement without polluting the environment. (Limestone deposits are actually composed of countless skeletons of ancient sea creatures.) In 2006 Dosier began teaching herself chemistry and materials science and experimenting with Sporosarcina pasteurii, bacteria that make a form of calcium carbonate called calcite when supplied with water, calcium, and urea.

While teaching architecture in the United Arab Emirates, she turned her second bedroom into a lab and set to work. She combined Sporosarcina with desert sand and nutrients and coaxed the bacteria into making a cement that would glue the material together into a usable brick. Some of her early bricks held shape but then dissolved underwater: “not good for areas with lots of rain,” she wryly noted in a 2013 TEDx talk. One batch simply would not cure, remaining wet after sitting on a shelf for three years. But after more than a hundred attempts, she one day threw together leftover materials from some failed tests and a week later discovered she had finally succeeded in making a hard, stable product. She won innovation awards and grants, attracted investors, and opened a greenhouse-like facility in North Carolina where bricks are grown in molds in a four-day process. “Why use fire to harden them when you can grow them?” she asked.

The world produces more than 1.2 trillion clay bricks a year, mostly in Asia, firing them in kilns that emit 800 million tons of CO2, according to bioMASON. But Sporosarcina emits none, plus it pulls CO2 out of the urea to make the calcite. The waste product is ammonia, which can be used to make fertilizer.

Constantz called bioMASON bricks a “neat idea” but said he doubted they would significantly affect global CO2 emissions. He maintains that cool new cement formulations and manufacturing processes are dead ends, and not just because they’re hard to market. After all, cement makes up only about 10% of the volume of finished concrete. What’s far more promising, he says, is the aggregate of sand and gravel that constitutes up to 80% of the mixture.

When Calera abandoned the cement business, Constantz started a company called Blue Planet that, like his earlier venture, uses seawater and waste CO2—but to make limestone rock rather than cement. Put that rock in your mix, and you’re locking away 1,200 pounds of CO2 per yard of concrete, far more than Calera cement would do on its own. You can even keep using Portland cement: just capture the cement plant’s emissions, turn them into gravel, and stash it in concrete foundations, sidewalks, and highways.

“We need solutions now that we can go out and actually make a difference with in the next 5 to 10 years. We don’t have 10 to 20 years to wait,” Constantz said. Using Blue Planet sand and gravel is “going to change the world.”

Apartments being built in Delhi, 2013. Despite improved efficiency and cleaner processes, cement production alone is responsible for nearly 5% (or 1.4 billion metric tons) of the carbon dioxide released into the atmosphere each year. CO2 emissions are only increasing, stoked by growth in the developing world.

John Harrison has come to a similar conclusion. At 68 years old he has a new girlfriend and revived aspirations to save the planet; he plans to sell some property to raise funds for his own rock-production project. Despite the cement industry’s refusal to change its methods, there’s still “an amazing potential” to use its emissions to make aggregate, he said. Capturing the CO2 is relatively easy; he’s already sketched out a process—involving magnesium, of course—he calls SynCarb.

The hard part, he said, is making it lucrative enough that the economics drive its wide adoption, making capitalism the engine of environmental repair. One possibility is to find a way to turn the waste chemicals of the aggregate-making process into profitable products. He just needs a bit of money to get started and make it all work. He doesn’t even care about patents this time; he’ll give his invention away to the world.

“I really do not think we have much time left with the atmosphere we have,” Harrison wrote in an e-mail. “It is time all the great thinkers of the world, combined with government funding, solved the problem in a manner similar to the way the atomic bomb was created. The problem is who is qualified to choose the thinkers! I hope to be one of them.”