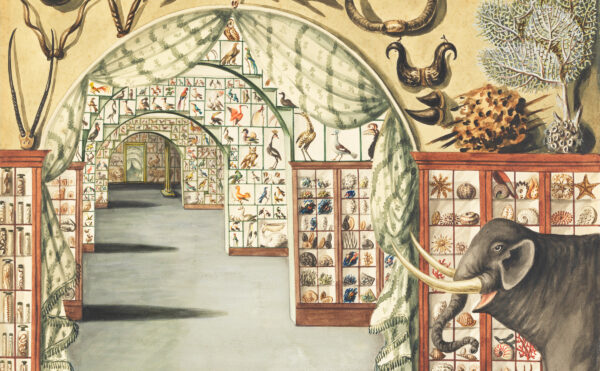

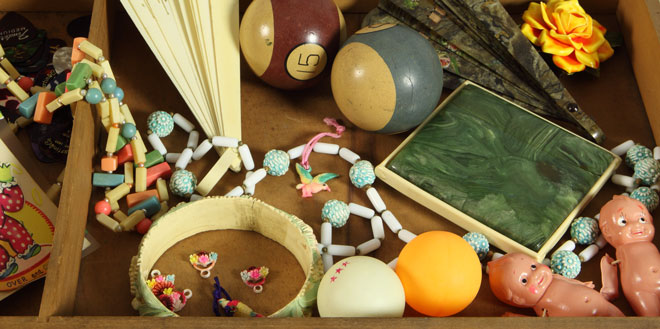

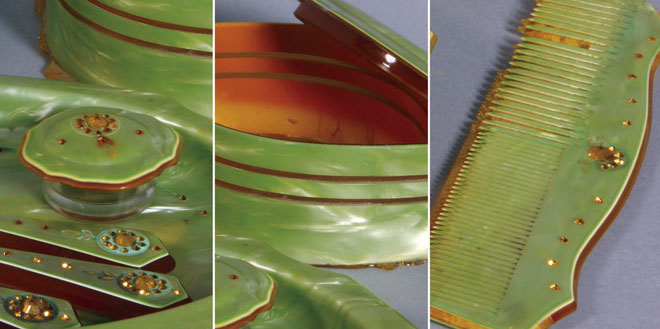

Celluloid, developed in the late 19th century, launched the modern age of man-made plastics. At first celluloid was an eternal substitute—an inexpensive imitation of ivory, tortoiseshell, and even linen. Women adorned themselves with celluloid jewelry and hair combs. Some had lavish celluloid “toilet sets” on their vanity tables: hand mirrors, combs, hairbrushes, nail buffers, and other grooming items manufactured in classic ivory tones or, later, in gleaming pearlescent hues set with rhinestones. Men and women alike wore detachable collars, cuffs, and shirtfronts stiffened with celluloid. People from all walks of life used toothbrushes with celluloid handles; children played with celluloid dolls and toys. Gamblers threw celluloid dice and dealt celluloid cards.

In short, celluloid had become an everyday material, just like the hundreds of plastics that would follow after World War II. But it remained an inessential replacement, and its makers sometimes struggled to find appropriate uses and markets for their products. And celluloid’s flaws, particularly its flammable nature, sometimes outweighed its virtues of cheapness and versatility. The material only found its true identity when it literally became the medium for another great modern invention: the motion picture.

Cotton and Camphor

Plastic, from the Greek word for molded, means just that: something that is capable of being molded or shaped. There have always been plastic materials in nature, including amber, rubber, and gutta-percha, all derived from tree sap. Even glass, moldable at high temperatures, is a natural plastic. The industrial age of the 19th century, with its faith in progress, turned to chemistry to invent a dazzling array of substances, including new plastics. Explosive fiber might seem an unlikely base for a moldable material, but the development of cellulose nitrate, also called nitrocellulose, was the first step toward celluloid.

Cellulose, composed of a chain of sugar molecules, is the building block of the cell walls of green plants. Thanks to cellulose, the most prevalent organic compound on Earth, wood is strong, paper is flexible, and cotton (which is 90% cellulose) can become fabric. While testing acids on organic materials in 1846, Swiss chemistry professor Christian Friedrich Schönbein found that a mixture of sulfuric and nitric acids drastically affected the cellulose in cotton. The white, fluffy fibers still looked the same, but they burned swiftly and fiercely.

Explosive fiber might seem an unlikely base for a moldable material, but the development of cellulose nitrate, also called nitrocellulose, was the first step toward celluloid.

This “guncotton” could be dissolved with organic solvents, and the resulting thick, syrupy liquid, called collodion, dried to a flexible film or a hard sheet, depending on the proportion of solvent. Collodion, first used in the late 1840s as a liquid bandage to protect skin, soon became important for photography. Turning this substance into a solid mass, however, required more experiments and ingredients. Camphor, another plant-based material, provided the key.

Camphor, familiar as a medicine and a moth repellent, is a crystalline compound usually derived from the wood and bark of the camphor laurel, a tree native to Asia. When combined with pyroxylin (partly nitrated cellulose) and other ingredients, camphor both dissolves the guncotton and makes it literally plastic, or moldable. Two new pyroxylin-based plastics—parkesine and xylonite—made short-lived appearances in the 1860s before falling into obscurity. Other similar materials followed, also with little success.

Mashing and Mixing

But man-made plastic soon found a future. In 1863 printer John Wesley Hyatt, a blacksmith’s son from upstate New York, noticed an intriguing advertisement. A New York City firm offered the then immense sum of $10,000 for an ivory substitute. The firm’s problem: billiards, formerly an upper-class amusement, was turning into a mass-market entertainment. The hard, uniform ivory of the highest quality essential to make balls came from the African ivory trade, which slaughtered elephants and forced enslaved men to carry the tusks on foot for hundreds of miles. Despite the barbarity of the trade, American firms worried more about potential shortages and the high manufacturing costs of turning raw ivory into billiard balls.

Hyatt jumped into the fray, experimenting with shellac (the resin from the female lac bug, which lives in forests in Thailand and India) and pressed wood pulp. This mixture, already used to make molded cases for daguerreotype photographs, was at first more suitable for smaller items like dominoes and checkers. Hyatt, ever resourceful, set up a company to make such game pieces, before beginning experiments with pyroxylin and camphor. He found it was not enough just to mix the two materials. In a process he patented in 1870, the two were pulverized separately—with dyes or pigments added to the pyroxylin pulp—then combined into a single mass, which was drained under pressure to remove excess water and molded under high heat. After further processing, including curing to remove excess camphor, the final substance was light, strong, relatively stable, and versatile (although it unfortunately retained the flammability of its guncotton component). Celluloid, the first successful synthetic plastic, had arrived.

Hyatt, along with his brother Isaiah Smith Hyatt, immediately put his invention to use. First they set up a company to make celluloid dental plates for false teeth, as an alternative to rubber. Then they established the Celluloid Manufacturing Company, which moved from Albany to Newark, New Jersey, in 1872. Here the brothers devised machinery for mixing the ingredients and new ways of manipulating the material. Blow molding, a process for making hollow items from celluloid tubes, was an important Hyatt development, leading to the mass production of millions of inexpensive toys and ornaments. Since it was clear and colorless if left undyed, celluloid could take on any tone, even mixed or mottled shades. Clever artisans fashioned celluloid into artificial ivory or coral, semiprecious stones, and tortoiseshell, which was especially in demand for hair combs and eyeglass frames. Early advertisements often promoted the material’s versatility and shape-shifting qualities (see sidebar). Because many people equated celluloid with guncotton, tragicomic urban legends about exploding combs and buttons abounded. Celluloid, though, was more dangerous to its makers than its consumers, with factory fires a common hazard.

Because many people equated celluloid with guncotton, tragicomic urban legends about exploding combs and buttons abounded.

But what of the billiard balls that led John Wesley Hyatt on his journey? They were probably never made wholly of celluloid. Instead, they were most likely composed of lighter, cheaper shellac and wood pulp, like his game pieces, with only a thin coating of collodion or celluloid to impart strength and color. Until the introduction of Bakelite in the early 20th century, there would be no wholly acceptable substitute for ivory in billiards. And though Hyatt made a passable imitation for many years, for some reason he never tried to claim the $10,000 prize.

“No More Washee Washee”

Celluloid’s key assets—it was naturally transparent, flexible, and waterproof—led to a particularly ingenious use. In the late 19th century, as industrialization accelerated and cities expanded, more Americans began working in offices and stores. This growing class of male and female workers—clerks, secretaries, typists, salespeople—was required to dress neatly and formally, often on modest salaries and while living in dirty, coal-fueled cities. Detachable collars and cuffs made of linen or cotton allowed shirts and blouses to be reworn while still looking fresh, but the detachable items needed to be washed, starched, and ironed regularly, just like the garments themselves. Paper collars and cuffs, though cheap, were not strong enough or dirt-resistant enough to be ideal substitutes, even when varnished.

Sheet celluloid, introduced in the mid-1870s, provided a solution, and again Hyatt led the way. He sandwiched linen or paper between thin sheets of transparent celluloid, then invented machines for cutting, heating, and bending this hybrid material into the form of collars, cuffs, and shirtfronts. The resulting long-lasting items never needed washing: they could just be rinsed clean. Hyatt himself applied for and received 11 patents for improvements to his invention, including methods of finishing the items for a more natural appearance.

Though celluloid linens never completely replaced true linens (particularly among the upper classes, who scorned such artificiality), they were moderately popular until shirt styles changed in the 1930s. Perfect, easy-wear shirts remained more of a hope than a reality: shirtfronts could pop or crack, stiff collar edges chafed cheeks and chins, and buttons rattled in the buttonholes of collars and cuffs. (Manufacturers advised wearers to wrap a small piece of chamois leather or an elastic band around the button’s shank to avoid this unwanted sound, and Hyatt soon patented a “Non-Rattling Celluloid Cuff.”) Some advertisers even managed to spin an unpleasant side effect into a virtue. On very scanty evidence the occasional camphor smell of the collars, released by body heat and perspiration, was hailed as a health benefit.

The greatest strength of celluloid collars, cuffs, and shirtfronts was their tough, waterproof, stain-resistant nature. Brightly colored trade cards, produced by manufacturers for distribution by retailers, emphasized this feature in a playful way, showing frogs and ducks wearing the items or children using them as boats and umbrellas. Other trade cards, however, expressed a darker side of American culture.

The greatest strength of celluloid collars, cuffs, and shirtfronts was their tough, waterproof, stain-resistant nature.

Starting with the California gold rush of 1848–55, significant numbers of Chinese immigrants, mostly men, came to the United States. Their numbers grew, with thousands working to construct the Central Pacific section of the transcontinental railroad in the 1860s. After the railroad boom they mostly moved to major cities, particularly San Francisco. Unofficially barred from most occupations because of prejudice and language barriers, many became restaurant workers or laundrymen. (Before electric washers, laundry work, traditionally done by working-class women, was dirty, difficult, and low status.) In the years after the Civil War nativist agitators unfairly blamed “coolies” for the lack of jobs and depressed wages. Anti-Chinese prejudice increased, culminating in the 1882 Chinese Exclusion Act, which essentially halted immigration from China. Some advertisements for celluloid collars and cuffs used such widespread racism as an advertising gimmick. On these trade cards wearers of celluloid linens celebrate the supposed American genius for technological innovation. They triumph over the stereotyped Chinese laundrymen, who speak pidgin English, have exaggerated “Oriental” features, and are shown as greedy and grasping.

One trade card features a laundryman attempting to collect from his customer, only to be dismissed because the man, newly arrayed in celluloid linens, has no more need of his services. Another, set in the “Gon Up Chinese Laundry” with Uncle Sam smiling in at the window, shows America as a proud young woman bearing a shield emblazoned with the word “Invention.” She points to the writing on the wall: “No More Chinese Cheap Labor—Celluloid Cuffs, Collars & Bosoms,” while the disconsolate laundryman, seated on his upturned washtub, wipes tears from his eyes. Yet another features two gentlemen rising from the ocean, wearing swimming trunks below and formal attire above. Facing a tiny, pigtailed laundryman weeping on the shore, they gesture boastfully to their cuffs and shirtfronts, showing how the items have resisted the briny waves. More laundrymen take to sea in their wooden washtubs, one with a sail marked “Off for China.” The caption states, “No More Washee Washee—Melican Man Wear Celluloid Collars and Cuffs.” Though anti-Chinese prejudice did not diminish, such mean-spirited advertisements were apparently short-lived, and celluloid manufacturers returned to touting the positive features of their products.

From Material to Medium

By the late 19th century, celluloid seemed destined to remain a second-class material—the stuff of inexpensive collars, hair combs, billiard balls, and baby rattles for the masses. Another development, however, was in store for this versatile substance. Previously, people had appreciated celluloid as a substitute, a plausible counterfeit of natural materials. But in its next chapter the pioneering synthetic plastic would no longer be an imitation. Instead, celluloid’s principal qualities—cheapness, flexibility, and transparency—would transform it from a material into a medium. Soon, the word celluloid would come to define not just the film stock spooling through thousands of cameras and projectors but the entire phenomenon of cinema itself.

Celluloid and photography had long been close cousins, for guncotton, the nitrated cellulose that formed the basis of the plastic, played an important role in early photography. In 1848 English photographer Frederick Scott Archer added potassium iodide to liquid collodion to make it sensitive to light. When poured carefully, the syrupy mixture would form a thin, adhesive layer on a glass plate. If the photographer exposed the plate in a camera, then quickly developed, washed, and fixed it while still wet, a negative image would form. After drying and varnishing, the collodion coating would be tough and waterproof, conserving the negative image. The photographer could then use the negative to make any number of positive prints on light-sensitive paper. Because both the glass and the collodion were transparent, the negatives and the resulting prints were sharp and highly detailed, exactly suiting 19th-century tastes for realistic pictures. Archer’s wet-collodion process quickly superseded daguerreotypes on copper plates and paper-negative calotypes, the two earliest photographic processes.

Even after later photographers devised dry-collodion and dry-gelatin methods, thus eliminating the need to prepare plates on the spot and develop them swiftly, the glass plates remained heavy, awkward, and breakable. Some photographers wondered whether there was a way to use collodion alone, without a glass support. In the early 1880s George Eastman, who manufactured photographic supplies in Rochester, New York, succeeded in devising the first practical and successful roll-film system. As a first step Eastman and his collaborator built on earlier experiments with gelatin-coated paper on a roll. After processing, the gelatin negative layer was stripped from the paper and used for printing, but at first this “stripping film” produced fuzzy images and was difficult to handle. After some improvements, however, Eastman was confident enough to use the film as the basis for his first great invention: the Kodak camera, introduced in 1888. With its simple, foolproof design, along with its unique, made-up name and memorable slogan of “You push the button and we do the rest,” the Kodak was a runaway best seller.

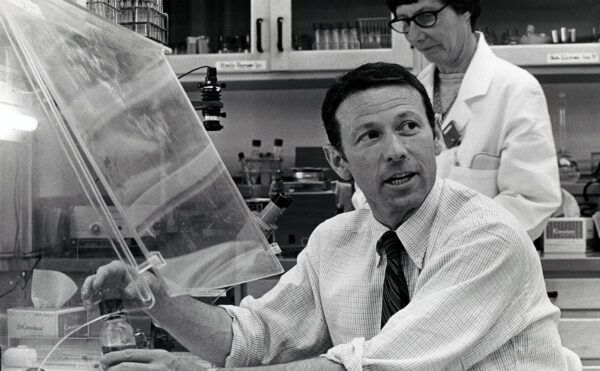

Eastman, however, was always trying to do better. While developing the Kodak, he had hired young chemist Henry Reichenbach to come up with a film that would be strong, flexible, and wholly transparent, requiring no stripping. It was already possible to create relatively thin layers of celluloid (as for collars and cuffs), but a photographic film would require an extremely thin, wholly uniform layer. Reichenbach used the well-known solvent amyl acetate to dilute celluloid for this purpose, and he soon determined the exact proportions of chemicals and the machinery needed to produce the film in bulk. He and Eastman filed patents for their inventions in 1889 and incorporated the film into the Kodak system. Despite a long-running patent dispute with a rival inventor (finally settled in 1913 with a $5 million payment from Eastman), celluloid-based film was a great success, reaping huge profits for the company.

The word celluloid would come to define not just the film stock spooling through thousands of cameras and projectors but the entire phenomenon of cinema itself.

The film was an immense boon to still photography, since amateurs could now develop and print it themselves rather than sending their Kodaks back to Rochester for processing and refilling. But nitrocellulose film (often simply called “nitrate film”) was an even greater gift to an emerging art form, since it made motion pictures possible. Early cinema experimenters had first tried using strips cut from celluloid blocks, but Reichenbach and Eastman’s film was obviously superior. When combined with money, talent, imagination, and ceaseless improvements to cameras and projectors, nitrate film—“trillions of miles” of it by 1928, according to one writer—created a new industry and transformed popular entertainment. Such classic movies as Fritz Lang’s Metropolis (1927), Charlie Chaplin’s Modern Times (1936), and Orson Welles’s Citizen Kane (1941) were all shot on nitrate film. And the “cels” of animation, the transparent, hand-painted sheets that brought Mickey Mouse and Bugs Bunny to life when filmed in sequence, were also made of nitrocellulose.

The material’s extreme flammability seemed a small price to pay for such bounty. Since movie projectors’ powerful electric lamps tended to overheat the fast-moving film, projection booths had to be lined with asbestos and equipped with safety shutters to prevent fires from consuming entire theaters. Early “safety films” made of cellulose acetate compounds had higher burning points but were more expensive and less durable than nitrate film. In 1950, just two years after Kodak introduced a greatly improved safety film made of cellulose triacetate, the company stopped making nitrocellulose film. The cinematic reign of celluloid, more than 50 years long, was finally over. Unfortunately, because of nitrate film’s instability, many early movies, particularly silent films from the dawn of cinema, have been lost forever, decomposed in their cans or burned in studio fires.

Celluloid Today

Although we still talk about the “celluloid heroes” of cinema and call motion pictures “films,” celluloid as a material is largely a thing of the past. Collectors snap up vintage celluloid toys, jewelry, and vanity sets on Internet auction sites, attracted by the charming design and craftsmanship shown in even the most humble, everyday items.

Surprisingly, though, this pioneering plastic continues to reign supreme in one arena. If you’ve ever bounced a Ping-Pong ball and smacked it across a table with a wooden paddle, you can appreciate celluloid’s lightness and toughness. Ping-Pong (or table tennis) began as an English parlor game in the 1880s, but really took off when celluloid balls replaced rubber or cork ones in 1900. Hollow celluloid balls, with their perfect bounce, have remained the standard for the game, even in international competitive play. As with Eastman’s photographic film, celluloid is most successful when valued for its own special qualities instead of standing in for another material. On the ping-pong table this remarkable synthetic plastic is no longer an imitation or a substitute; it is unquestionably the real thing.