The Color of Extraction

Encountering rare earths in art, environments, and the phone in my pocket.

Encountering rare earths in art, environments, and the phone in my pocket.

Europium, terbium, and I are very close. These rare earth elements and several others illuminate the liquid crystal display of my iPhone screen each time I pick it up, which, according to my last Screen Time data report, was 673 times. The magnetic properties of neodymium and other rare earths enable my speaker, microphone, and vibration to function. With devices fueled by these elements and other critical metals in semiconductors and batteries (lithium and gallium), I carry a world of metallic multimedia and connectivity in my pocket. Less physically proximate but equally essential are giant wind turbines embedded with these metals that generate energy for a power grid that charges my little phone.

One of the Institute’s newest digital exhibitions, Critical Metals: The Chemistry of Light, explores Carl Auer van Welsbach’s early uses of cerium and thorium in lamp mantles that lit the 1890s, long before the light of cell phone screens kept us awake. Welsbach was a student of Robert Bunsen—of Bunsen burner fame—who also used spectroscopy to identify elements. The first rare earth elements were discovered a century earlier in 1780s Sweden; others were discovered through 1913 with the help of X-ray spectroscopy.

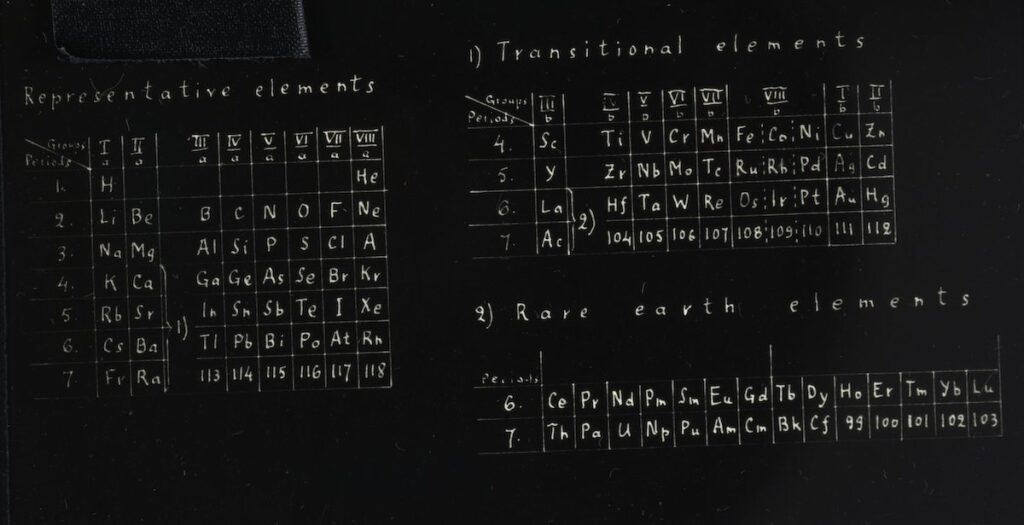

Series Table of Representative Elements with Supplementary Tabulations for Transitional and Rare Earth Elements, illustration from Types of Graphic Representation of the Periodic System of Chemical Elements by Edward G. Mazurs, 1957.

Rare earths are abundant but hard to identify. They are present in small quantities and bound to each other and other elements. The challenge of separating them requires acid baths that produce toxic waste, though contemporary labs are pioneering more sustainable methods.

Rare earth elements were not always coveted, though. To extract pure uranium for a nuclear fission reaction, chemists working on the atomic bomb separated rare earths from uranium. Frank Spedding, the chemist central to that wartime work, later founded the Ames National Laboratory at Iowa State University, leading it from 1947 to 1968. Today the Ames Lab remains a leader in rare earths research.

In 1965 a Holiday Inn sign that read “Welcome Rare Earthers” greeted scientists as they gathered for the 5th Annual Rare Earth Research Conference in the town of Ames. The person who stood on a ladder and pressed each of the giant letters into the analog sign likely did not know that these elements were making a big commercial debut that year as well: Europium-doped yttrium salts lit the colors of new TV sets. NBC, heralded by a new rainbow peacock logo, broadcast Disney’s Wide World of Color.

We are all “rare earthers” now, children of computers and screens, though the metals’ geological origins, as well as the impacts on humans and the environment from mining them, remain removed from most of us. The mining industry responds to and drives our needs and desire.

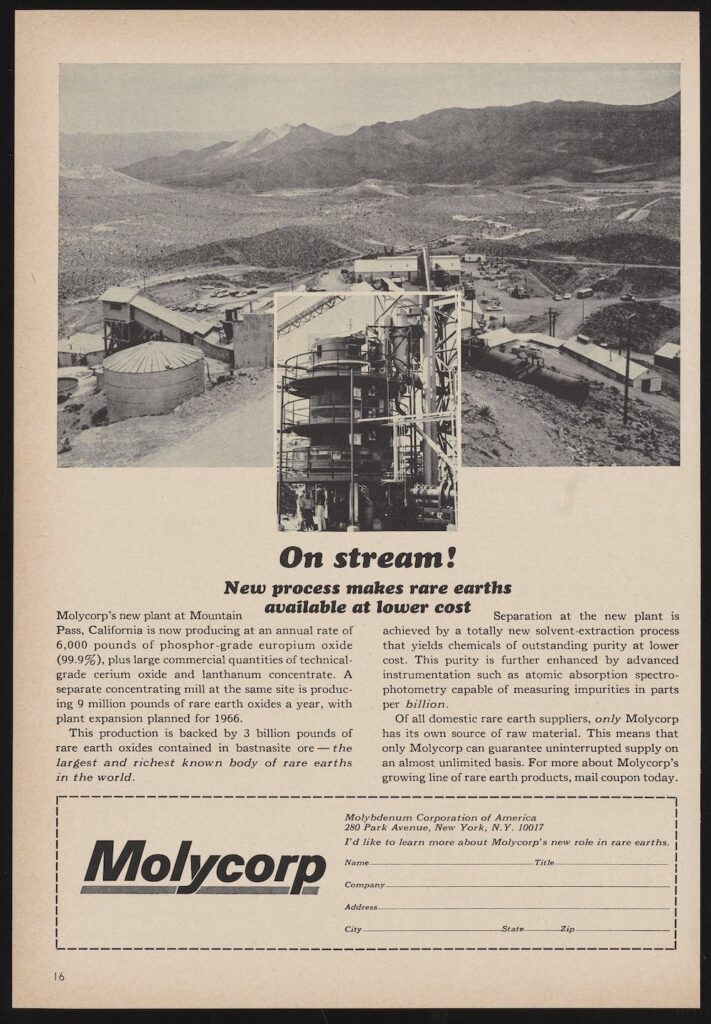

“On stream! New process makes rare earths available at lower cost,” announces a 1965 Molycorp advertisement that promises phosphor-grade europium oxide (add a red glow to your TV show!) as well as cerium and lanthanum, made possible by spectrophotometry instrumentation and a new solvent-based extraction process at the Mountain Pass Mine in southern California.

By 2002 the same separation facility celebrated in this ad closed after 300,000 gallons of radioactive waste spilled into the Mojave Desert. In response to changing environmental regulations and shifting global trade networks, the mine has reopened and reclosed several times over the past 20 years. Mountain Pass, now owned by MP Materials, is the only rare earths mine that remains in the United States.

Despite our constant and even intimate reliance on rare earth products (a pacemaker’s semiconductor may support your grandparent’s heartbeat, for example), few of us will ever directly experience the source of these elements. We view mining sites only through descriptions and satellite images.

In 2012 journalist Jay Greene described the Mountain Pass Mine walls as “etched with striations in varying shades of black . . . notched, every 75 feet or so, creating steps that only a giant could use to climb out of the pit.” NASA’s Earth Observatory satellite captured China’s Bayan Obo mine in two images that compare the mine’s expansion over a five-year span, but pictures can’t fully convey the impact of larger tailings ponds of waste that contaminate groundwater and soil.

Glass with uranium, europium, and terbium glows under black light in the Enabling Transparency exhibition, 2022.

Seattle-based glass artist Anna Mlasowsky wanted to study the history of rare earths to further understand the origin and environmental impact of the materials she uses. Striking hues lure artists like Mlasowsky, who mix erbium, terbium, europium, neodymium, and praseodymium with clear glass. Cerium is used to polish glass surfaces and to prevent unwanted color shifts due to impurities. Rare earth elements also enable some glasses to change color under black light, fluorescent light, and daylight.

Through a Science History Institute fellowship, Mlasowsky studied our collections, developed relationships with environmental historians and scientists, and created Enabling Transparency, an exhibition that launched in conjunction with the “Colors, Metals, and Environments” symposium and is currently on view in our lobby through July 2023. Mlasowsky, who was the Institute’s first artist-in-residence, also details her research and studio work on Instagram and the research page of her website.

Mine Vessel, a highlight of the exhibition, is an erbium-pink glass sculpture and scale model of Mountain Pass Mine. From Google Earth images, Mlasowsky digitally traced each stepped layer of the open-pit mine, cut those forms into wood templates, and then created molds to cast pink erbium-doped glass.

The resulting piece, which Mlasowsky donated to the Science History Institute, is part of a larger series of vessels depicting mines in Bayan Obo, China and Pittinga, Brazil. While secretaries of commerce and CEOs might emphasize difference to dominate a market, Mlasowsky’s work functions as an homage to the similarities among these sites of extraction.

In Mlasowsky’s symposium talk, she referenced a complex recent crisis during which environmental regulations increased, prices for art glass materials rose by 150%, and some U.S. art glass suppliers closed, reducing supply. In Portland residents sued a leading art glass manufacturer for air pollution containing heavy metals, which prompted the investigation of a second manufacturer. Eventually the state of Oregon passed new air quality regulations for various industries and the EPA investigated the 14 U.S. art glass companies that existed in 2016. Some manufacturers, unable to invest in filtration systems, closed. In part the story raises questions about what support small, niche manufacturers might need to produce in a more sustainable way in the United States.

Meanwhile, Mlasowsky located a new source of glass that is not only cheaper—$1 versus $10 a pound—but also more environmentally responsible. Gabbert Cullet Company in West Virginia promises “Mountains of Glass” in a “Rainbow of Glass Colors!” left behind by a defunct tableware and pane glass industry that originated when rare earth additives were affordable, so Mlasowsky had 2,000 pounds of it shipped to her home and studio in Seattle. This creative sourcing and reuse echoes some of the recycling and sustainability trends in labs such as the University of Pennsylvania’s Center for Sustainable Separation of Metals. Some leaders in wind power seek alternatives to rare earths to reduce costs and decrease the impact of mining.

As our knowledge of the environmental and human toll of rare earth materials has increased, enterprising artists, scientists, governments, and consumers all seek more ecological and affordable ways to access and use these essential elements.

The Science History Institute’s Othmer Library announces the winners of its 2025 After Hours comic book caption contest.

Collaboration, connection, and critique over pizza.

How to read a book when the pages are out of order.

Copy the above HTML to republish this content. We have formatted the material to follow our guidelines, which include our credit requirements. Please review our full list of guidelines for more information. By republishing this content, you agree to our republication requirements.