A Crushing Task

On the hunt for the historical sources of an underappreciated field: mechanochemistry.

On the hunt for the historical sources of an underappreciated field: mechanochemistry.

Not long ago I was chatting with a chemistry department administrator at one of those proverbial “large midwestern universities.” Taking another sip of my drink, I asked a rude question: Which fields of chemistry got the most prestige? He described a hierarchy descending from analytical chemists pleased by their elegant deductions, down to the chemical biologists sullied while corralling an untidy herd of biomolecules.

Then I asked where mechanochemistry fit in this ranking. “Wait,” he said. “What’s mechanochemistry?”

It was not the answer I was expecting.

I’ve been exploring the history of mechanochemistry for a few years now. The Institute has a partnership with the National Science Foundation’s Center for the Mechanical Control of Chemistry (CMCC). We’re helping scientists and the public understand the societal impacts of this science by putting today’s research advances into historical perspective. We’ve previously explored mechanochemistry in a Distillations podcast episode and a digital exhibition.

But mechanochemistry is clearly not yet familiar, even to chemists. It’s generally not included in undergraduate textbooks, says Maya Costales, a PhD candidate chemist and part of the CMCC research team. “I do not think I’d heard it mentioned even once in my undergrad classes,” she told me.

So, for those new to the subject, mechanochemistry is the study of how mechanical force affects chemical reactions. It’s becoming significant now as part of what’s called “green chemistry,” since mechanochemical techniques offer the potential for reducing the need for toxic solvents and energy-intensive reactions.

While the effects of heat, light, and electrical charge on chemical reactions became lively subjects of research during the 20th century, mechanical force has clearly received much less attention. Historically, mechanochemistry has been associated with polymers, colloids, and tribology (the study of friction and lubrication). Although one of the founders of physical chemistry, Wilhelm Ostwald, coined the term back in 1919, the field is no more present in standard histories of chemistry than it is in undergraduate chemistry textbooks.

As our partnership with CMCC expands, we’re exploring our collections for sources that can help write the history of mechanochemistry. But mechanochemistry can be a tricky subject to track down. Geopolitical divides during the 20th century meant key research was often published first in Russian or Japanese and not always translated into English. Other times, U.S. and European researchers described using crushing tools like ball mills to prepare materials, without realizing they had initiated chemical reactions mechanically. And the language of mechanochemistry has changed over time, making for misleading connections between historical sources and today’s science.

For instance, take one of the most seemingly straightforwardly mechanochemical sources in the Othmer Library: Pierce Mason Travis’s 1928 Mechanochemistry and the colloid mill. Written at a moment when colloid science was among the most hyped and hopeful fields of scientific research, Mason used mechanochemistry to mean “this new science of mechanical dispersion,” since it involved dispersion through mechanical rather than chemical means. But as Costales pointed out to me, “the definition used in this 1928 book is not at all in line with the definition of mechanochemistry today, so when it comes to research from that time period the term may be used for things we do not consider mechanochemical now.”

Our starting point in the history of mechanochemistry is a series of papers published between 2000 and 2018 in scientific journals by physicist-turned-mechanochemistry historian Laszlo Takacs. Like any historian worth reading, Takacs had an agenda in writing history. Reading between the lines of his work, we can see that he’s interested in elevating the status of mechanochemistry by recovering its deeper history and connecting it to celebrated historical scientists like Michael Faraday.

Takacs came to history through his science research, in particular his personal discovery that his field’s work in mechanical alloying during the 1980s shared much in common with a separate field called mechanochemistry. Takacs points out that mechanical alloying arose separately from mechanochemistry, in the late 1960s, and it wasn’t until the 1980s that he discovered how much the two fields had in common.

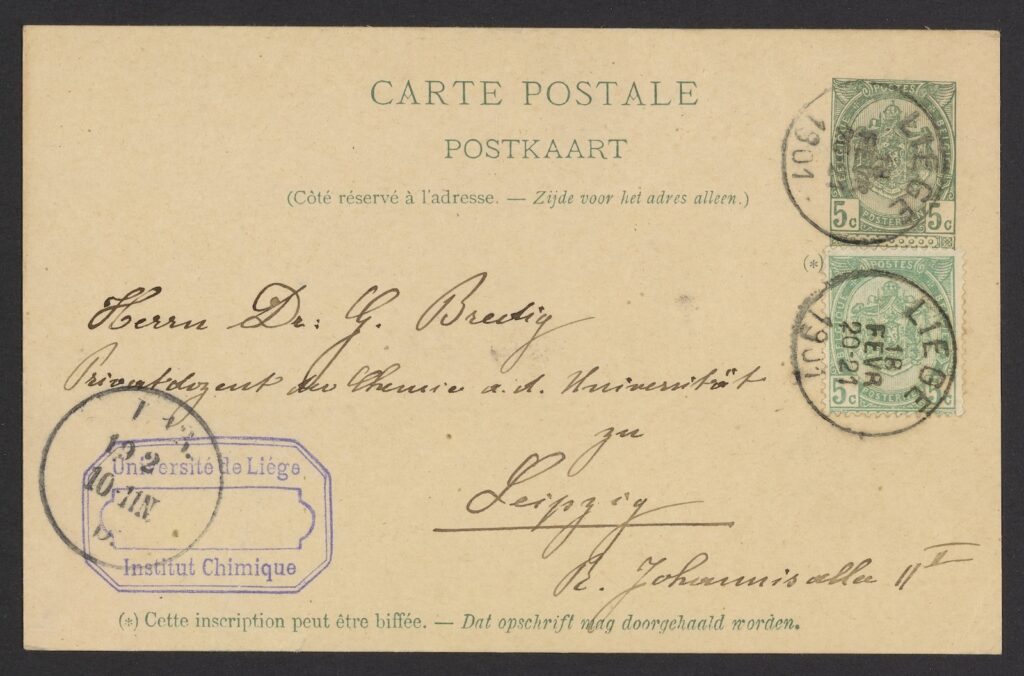

Takacs argues that the first extensive investigations of the chemical effects of crushing and grinding were carried out by the Belgian chemist Walthère Spring in the 1880s and the U.S. chemist Matthew Carey Lea a few years later. Spring used a powerful press as part of his research into how mechanical pressure affected mineral formation. The Science History Institute holds an acknowledgment post card Spring sent to Georg Bredig.

The Institute’s holdings on Matthew Carey Lea are more extensive—fitting, since Lea was a member of one of Philadelphia’s most distinguished learned families. Lea is a key figure in the origins of mechanochemistry for his systematic investigations into the use of grinding to initiate chemical reactions in various metallic salts. In one experiment, Lea used a mortar and pestle to demonstrate that mercuric chloride and silver chloride decompose differently when triturated (or ground) in a mortar than when they are heated. Lea broke new ground by showing that mechanical action could produce chemical reactions different from those initiated by heat or light.

The Institute holds several books by Lea, as well as a 10-page biography written by the chemist historian Edgar Fahs Smith (part of Smith’s effort to persuade U.S. chemistry students that the country had a history of distinguished chemists). Most interesting visually are bookplates featuring Lea’s portrait, adorning books originally purchased by the Franklin Institute with a bequest from Lea’s estate. (The Othmer Library subsequently acquired these books from the Franklin Institute.)

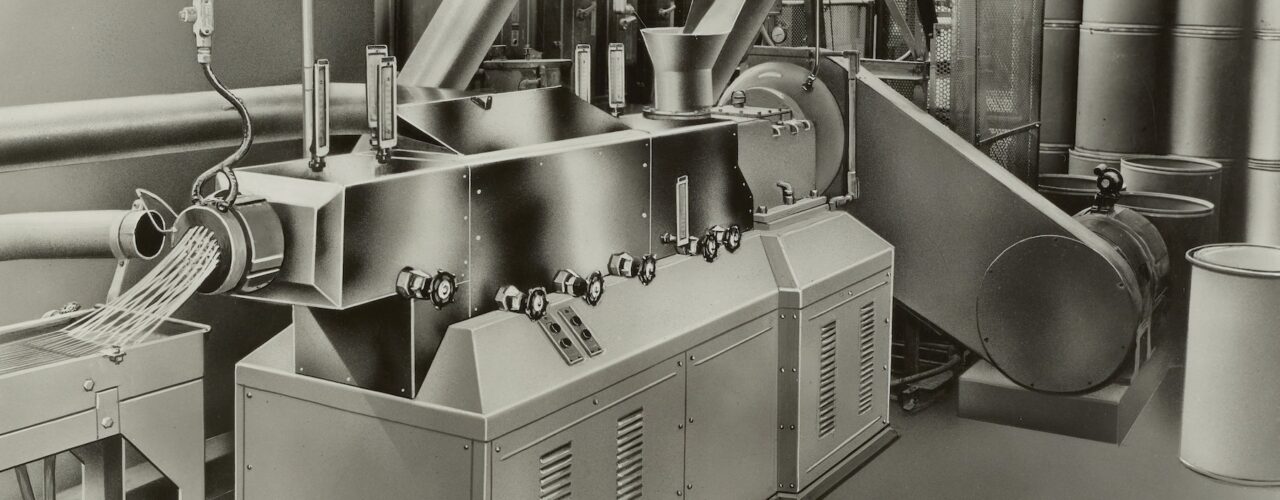

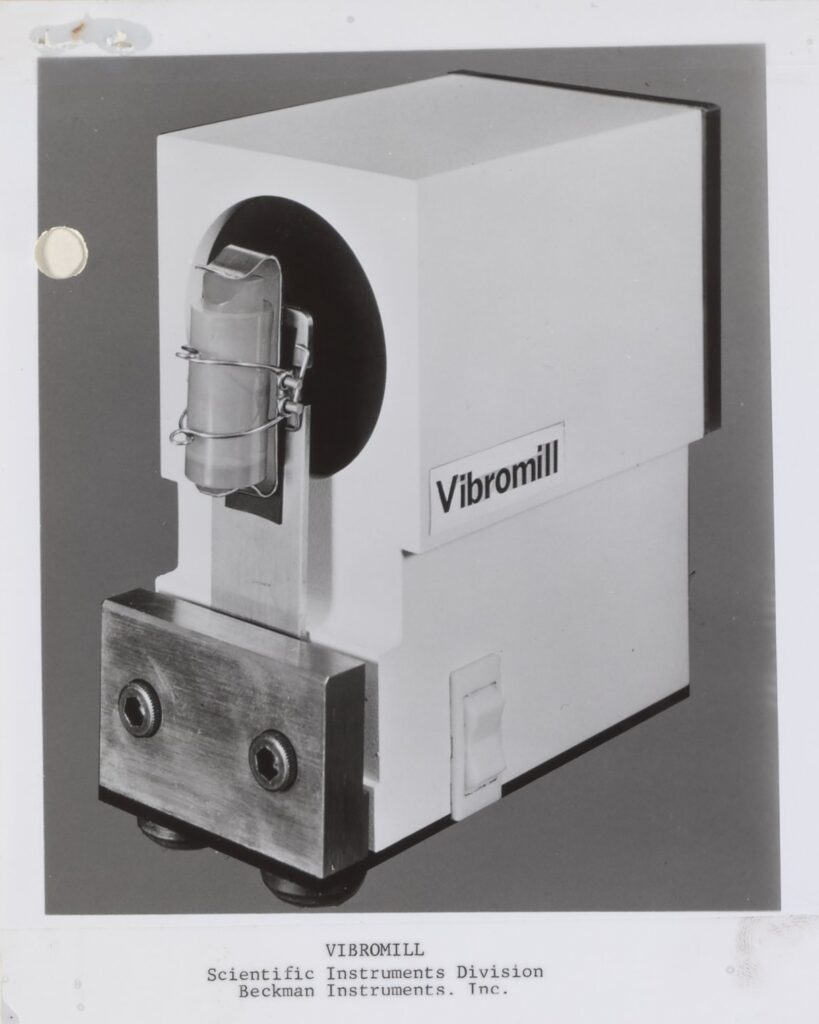

Tracking the history of key mechanochemical tools like the mortar and pestle offers another avenue for historical exploration. The Institute’s museum holds more than 20 different mortars, variously made of wood, granite, marble, glass, ceramic, and brass. Newer tools used in mechanochemistry can be found in photographs, like a vibrational mill (pictured below) and a twin-screw extruder (pictured at top).

Some of the higher-tech tools used in mechanochemistry today are described in “Introducing Mechanochemistry,” published by Chemistry World in 2018. These include atomic force microscopy (AFM) for applying pressure directly to individual atoms. Our oral history collection includes several interviews sponsored by the Center for Nanotechnology and Society, conducted between 2005 and 2011, that describe the development and use of the atomic force microscope.

An article titled “Chemistry, Microscopy, and the Nano World” from the 2006 issue of our Chemical Heritage magazine (now Distillations) draws on these interviews to connect Robert Hooke’s 17th-century work to AFM usage in the 21st century. These interviews suggest a new historical avenue to explore in terms of the connections between mechanochemistry and nanotechnology.

Other oral history interviews shed light on mechanochemistry’s history by describing work that is mechanochemical without being explicitly identified as such. For instance, the chemist and nanotechnologist Mark A. Ratner describes research in Eugene Rochow’s Harvar laboratory. By 1945 Rochow had developed a method of using copper to catalyze a direct reaction for creating silicon polymers. Now known as the Müller-Rochow process, this method underlies the silicone industry. (Think of flexible ice cube trays and heat resistant rubber-like spatulas.)

One “hot as blue hell” summer sometime between 1960 and 1964, Ratner was asked to see if the reaction could be extended to work with boron in place of silicon. Ratner used a ball mill to combine boron and copper. “You just run the process for several hours,” he told our interviewers. “What happens is you essentially form copper impurities, and it’s almost certainly true that copper impurities are responsible for catalysis.” Ratner ran this experiment while dressed for the weather. As Ratner recalled, Rochow “walked by, took one look in, and his face turned green. He didn’t say anything, but I think he was pretty upset to see somebody working in a lab in flip-flops.”

This is a mechanochemical reaction, Dawson Michael Smith, my CMCC colleague and graduate student in chemistry points out, “but the details are more subtle than the interview would lead you to believe.” Ball milling integrates bits of silicon or boron into the surface of copper particles, which provide the extra electrons needed for the reaction to proceed smoothly, Smith explains. This mechanochemical process creates an intermetallic, “which is sort of like a metal alloy but different in that the atoms are more orderly.”

Interviews like Ratner’s suggest that mechanochemical techniques may have been more widely used in the past than is commonly appreciated, even if how they worked was not fully understood. We don’t see mechanochemistry because historical actors may not have realized they were doing it.

Another reason mechanochemistry is not better known in the United States today may lay in Cold War divisions. As W. F. Wilson wrote in the editor’s preface to Mechanochemistry of Polymers in 1964, “mechanochemistry is a term that may not be so well known in the Western World as it is in the Soviet Union,” since Soviet scientists had devoted “greater effort” to “investigating reactions induced by mechanical energy.”

The book was a translation of a Russian text by Soviet professor N. K. Baramboim, commissioned by W. F. Wilson’s employer, the Rubber and Plastics Research Association of Great Britain. Baramboim synthesized research on how polymers break down under mechanical forces—why rubbers and plastics fail under repeated mechanical stress—as well as work exploring the induction of new chemical reactions using highly reactive polymer radicals formed through mechano-degradation. Baramboim saw mechanochemistry as a “very promising and vigorously developing line of investigation in many countries and especially in the U.S.S.R.”

Indeed, the 1960s were a particularly significant era for mechanochemistry. In “Two important periods in the history of mechanochemistry,” Laszlo Takacs points out that the first scientific meeting dedicated to mechanochemistry was organized in the Soviet Union in 1968. Takacs identifies two colloid chemists who played key roles in this development: the Russian Petr Aleksandrovich Rebinder and the German Peter Adolf Thiessen.

Early in his career, Rebinder (sometimes transliterated from Cyrillic as Rehbinder) studied how smearing various agents on the interface surface (surfactants) could ease cutting hard materials, now known as the Rehbinder effect. He then enjoyed a successful career in Soviet institutions of science, chairing the Department of Colloid Chemistry at Moscow State University and helping to set science policy for Soviet chemistry.

Most of Thiessen’s career also happened under totalitarian regimes. After joining the Nazi Party in 1925, Thiessen went on to become director of the Kaiser-Wilhelm Institut für Physikalische Chemie und Elektrochemie, and was deeply involved in German war research during World War II. In April 1945 he made contact with a Soviet chemist (and Army major) rounding up German science leaders as part of Operation Osoaviakhim, the U.S.S.R.’s equivalent of the U.S. Operation Paperclip that captured rocket scientist Wernher von Braun.

Rebinder and Thiessen remained in contact, and an East German delegation was part of the special session on mechanochemistry that Rebinder organized as chair of the 6th All-Soviet Conference on Colloid Chemistry in 1968. That same year a dedicated research group was established under the leadership of V. V. Boldyrev in the Siberian city of Novosibirsk, later named the Institute of Solid State Chemistry and Mechanochemistry.

In addition to the translation mentioned above, the Othmer Library holds a variety of publications relevant to these events. Thiessen wrote the foreword to a 1984 book Tribochemistry, while Rehbinder was co-author on the 1960 book Effect of surface-active media on the deformation of metals, and editor of the 1965 book The use of surfactants in the petroleum industry. Boldyrev wrote The Control of the Reactivity of Solids, published in English translation in 1979, as well as a fascinating historical reflection, “Mechanochemistry in Siberia,” published in 2018.

Writing the history of mechanochemistry is going to be a challenging quest that professional historians of science have only just begun. For people eager to embark on that challenge, the starting point for published materials are the Library of Congress Subject Headings “Mechanical Alloying” and “Mechanical Chemistry.”

This quest may also lead us into fields of chemistry that have a great deal of significance and plenty of workers, but less prestige. As Andrew Ede wrote in 2007 in The Rise and Decline of Colloid Science in North America, 1900-1935:

All kinds of crucial effects happen at interfaces and are shaped by the mechanical forces of crushing and grinding that occur as surfaces interact. A willingness to look for new historical sources and less well-known fields of research can help us to appreciate their significance.

Thanks to our partners at the Center for the Mechanical Control of Chemistry, including Professor James D. Batteas, Professor Robert W. Carpick, Maya Costales, Dawson Michael Smith, and William Oprisu.

Funding for the Mechanochemistry: The Science of Crush digital exhibition was provided by the Center for the Mechanical Control of Chemistry under NSF Grant #CHE-2303044.

Unwrapping the mystery of a Styrofoam Santa in our collections.

New World ingredients in Old World dyes.

How a Jewish scientist’s intellectual property became a lifeline in his journey from Nazi Europe to the United States.

Copy the above HTML to republish this content. We have formatted the material to follow our guidelines, which include our credit requirements. Please review our full list of guidelines for more information. By republishing this content, you agree to our republication requirements.